|

Maanshan Durmapress Machinery Technology Co., LTD

|

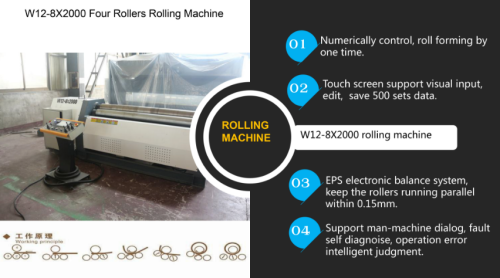

hydraulic 4 rolls symmetrical plate bending roller machine price

| Qty (Set/Sets) | Unit Price (17900.0~18000.0 USD) |

| 1 | 18000 |

| 2 + | 17900 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

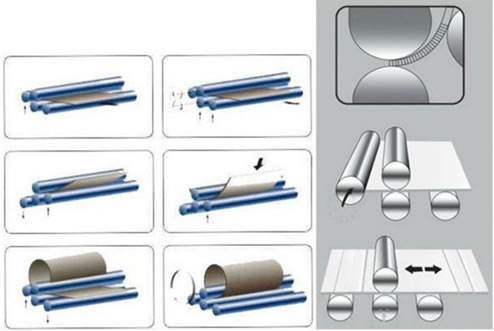

the structure of the machine is symmtrical 3-roll, two lower rolls are symmetrical central location, so it is convenient for machine vertical movement

This equipment composed of work frame , upper roll device , main drive device, down roll

device, side roll device, overturn device ,hydraulic system(parts) , electricity system(parts),

and lubricate device.

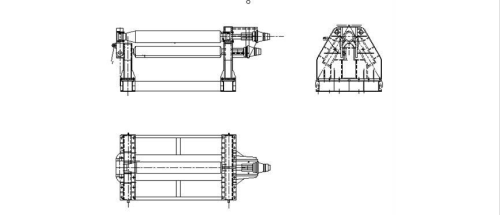

Work frame:

Body from the base, a fixed side frame and the tip side of the rack, and each part is steel

welded structure.Were fixed with bolts on both sides of the rack in the base and sides

of the rack will be used to connect beams connected to rigidity good.Both sides of the rack

up roller and side rollers with movement of rail, fixed on the side of the rack with roller

bearing for half of the closed frame structure, has overturned overturned side rack

shelf support devices. Coil force in the process of both sides of the rack by the bear from

the base not only supports the weight of the machine to ensure the accuracy of the role of

equipment, but also enables a torque between the drive and chassis balance, and will join

into one machine. In the now traditional large-scale four-roller bending machine body and

the main gear is separate from the base installation.

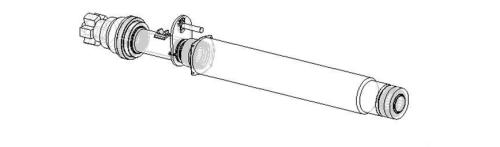

Upper roll device

The up roller gear drive from the main for turning, the ends of the SP-1 bearing support, drive-side

through the flat key, off the main drive gear and connect the device to transfer torque, tip-side with

the protection of Steel .

The material of the up roller is 42CrMo, heat hardening is HB220-300.

main drive device:

By the Y2 motor, three speed reduction gear, transmission torque to the roller.

In the high speed shaft of reducer with putting

the power hydraulic brake.Power supply is 380V/50Hz.

3-4:Down roller device:

Down roller supports under the bearing, the bearing housings on both

sides of the rack mounted inside the track, the bottom

of the piston and cylinder connected. Bearing in the liquid under pressure

can rise and fall along the rail, according to the size

of the thrust rod, steel plate under the roller clamping force required by the

hydraulic system pressure control valve be adjusted.

Addition of the down lower rollers can roll adjustment, improve the accuracy

of product under the same material heat treatment

hardening is HB220-280.

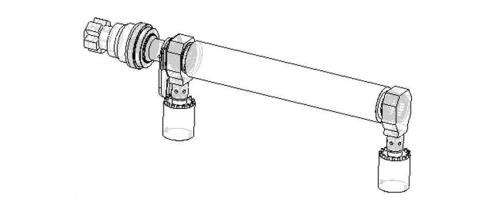

3-5, Side roller device:

Side of the roller bearing in the radial bearing pedestal, bearing on both sides

of the rack mounted inside the track, the bottom

of the piston and oil cylinder connected. Bearing in the liquid under pressure,

can be tilted up and down along the rail, the size

of the piston rod of the thrust force according to the needs of steel plate by

the hydraulic system pressure control valve be adjusted.

The side roll quality alloy steel, heat treatment hardening is HB220-280.

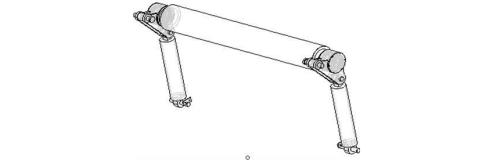

3-6:Overturn device:

Overturn device through the oil cylinder , hinges torn off and driving overturned on

a roller bearing aircraft overturned in order to remove products.

3-7:Hydraulic system(parts)

Hydraulic system consists of gear pump, valve, fluid connectors, hydraulic accessories.

Superposition valve series hydraulic valves used, piping layout simple and easy to

maintain debugging.

System consists of three circuit composed of overpressure protection and pressure

control loops, synchronization loop, speed loop.

Loop through the main relief valve pressure regulator conditioning system working

pressure. System working pressure 19.5Mpa.

3-8:Electricity system(parts)

Electrical control system includes the electrical box, operation control panel, hand-held

button.Main switch with short circuit protection

and the main motor overload protection. Reversible motor contactor control by the

exchange;

control circuit is controlled by PLC programmable controller system, relay less reliable

action and long life. Control cabinet with the

completion of the process of rolling all products control buttons, lights, etc. to the

operation of the machine control and status control.

FAQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your

nearest port or address with postcode. we have reliable shipping agent to insure the safe

convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Our Service

1 We have more than ten years of experience in the production of machine tools, and we have a good team

for your service

2. We have strict quality control system.

3.We accept OEM&ODM according to your requirement.

4.We will deliver as soon as possible once place the orders.

5.You can contact us at any time .

We can manufacture all kinds of the machines, if you have any request, please contact us soon. Feel free to

email me, we will reply you within 12 hours.

.jpg)

.jpg)