|

Maanshan Durmapress Machinery Technology Co., LTD

|

C-Frame Mechanical Power Press

| Qty (Set/Sets) | Unit Price (5900.0~6000.0 USD) |

| 1 | 6000 |

| 2 + | 5900 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Built-in block collapsed overload protection device, the structure is simple, if slider after

overload, fuse collapsed destroyed to protect the mac

Product Description

1. High rigidity and precision frame, nodular cast iron body:

Internal stress of the body has been eliminated through heat treatment, ensuring a long-time working stability of the machine.

2. High accuracy:

Main components as crankshaft, gears, drive shafts and other parts are hardened by heat treatment before machine-shaping, ensuring stable and accurate performance for a long time.

3. Automatic manufacturing process saves human input and improves production efficiency.

Automatic feeding device provides services as feeding error detection,plate sharing, contributing to automatic producing process.

Reduce costs and improve production efficiency.

4. Slide adjust device:

There are two adjustment ways:manual adjustment and electrical adjustment.It works convenient and reliable,safety,fast.

Technical parameter:

Name | J23-40T | |

Nominal force(KW) | 400 | |

Nominal force stroke(mm) | 4 | |

Slide stroke(mm) | 100 | |

Stroke frequency(times/min) | 50 | |

Max closed height(mm) | 320 | |

Max Die height(mm) | 220 | |

Closed height adjustment(mm) | 70 | |

Distance between slider center and the fuselage | 230 | |

Work table size | F-B(mm) | 410 |

L-R(mm) | 640 | |

Diameter of blank-holding hole | F-B(mm) | 180 |

L-R(mm) | 300 | |

diameter(mm) | 160 | |

Slide bottom size diameter(mm) | F-B(mm) | 230 |

L-R(mm) | 260 | |

Hole size for die handle | diameter(mm) | 50 |

Depth (mm) | 80 | |

The distance between columns (mm) | 290 | |

Net distance between work table to guide rail (mm) | 410 | |

Backing board thickness(mm) | 80 | |

Body tilting angle( °) | 25 | |

Motor | rate(kw) | 4 |

speed(r/s) | 1420 | |

Frame dimension | (mm) | 1500*1000*2400 |

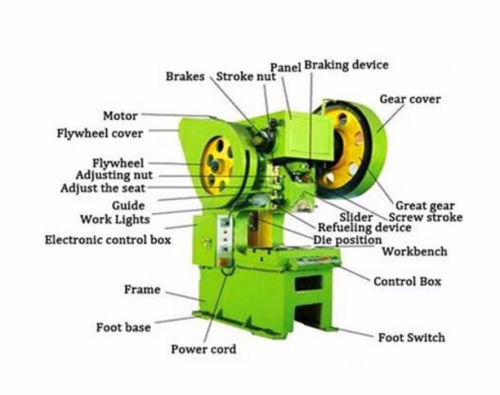

Photos of machine:

OUR TEAM

DURMA SUCCESSFUL CASE

DURMA OFFICE

Packing & Delivery

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

.jpg)

.jpg)