|

Maanshan Durmapress Machinery Technology Co., LTD

|

90Ton hydraulic Ironworkers machine

| Price: | 6850.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

900KN

punch holes thickness:

20 mm (max)

biggest holes diameter:

30mm

throat depth:

335mm

cutting biggest thickness of flat bar:

20 mm

Specifications

DIW-90Ton hydraulic Ironworkers,hydraulic Iron worker machine

1.It adopts hydraulic driving system

2.it can do the hole punch

DIW-90Ton hydraulic Ironworkers,hydraulic Iron worker machine

Hydraulic 66-200ton double cylinder ironworker

1. Introduction:

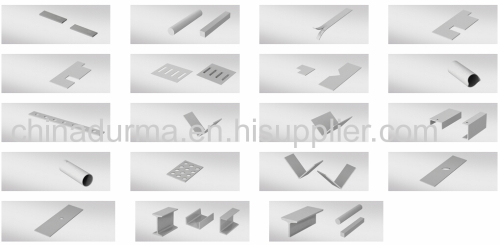

H(Q35Y) series industrial-grade hydraulic ironworker is a combined punching and shearing machine, featuring multiple functions, including: punch all kinds of holes (round, square, oblong hole), louver punch, angle steel shear, flat steel shear, profile steel shear(channel, I-beam, round/square bar, T-bar shear), notch, V-notch, bending, angle bending. We can design any special tools according to your metal fabricating requirements.

It is widely used in steel structure, high voltage tower, telecommunication tower, large rigid frame bridge, military and air craft and other metal fabricating industries. Standard equipped with quick-change coupling nut & sleeve, squaring arm with scale, electronic back gauge, gauging table with stops, punching base table, safety guards and more.

2. Optional configuration:

Automatic Holding System: The automatic holding system can be chosen to set up in angle steel shearing and plate shearing work position. Additionally, the holders will fix the position of work piece in order to save time and improve working efficiency.

Temperature cooling system: When the machine is working, you can read the temperature of oil through the monitoring screen. If the oil temperature goes higher than 55 degree which is the default configuration, the inside cooling system will run automatically to decrease oil temperature in order to protect hydraulic system.

Dual working system: At this condition, punching and shearing position can work synchronously, suitable for volume-production.

Introduction:

It adopts hydraulic driving system and is the latest punching and shearing machine in our country, Various metallates,

square steel, Round steel, angle steel, channel steel and I-iron can be cut, punched and notched by this machine. It is also equipped with a stop device for cutting.

Main parameter:

No. | Function | Item | Unit | 90Ton |

1 | Punching pressure | ton | 90 | |

2 | Shearing Plate | Angle of shearing | ° | 8° |

Max shearing thickness | mm | 20 | ||

Flat bar | (W×T) | 10×480 | ||

mm | 20×330 | |||

3 | Shearing bar | Round steel | mm | 60 |

Square steel | mm | 50×50 | ||

90°shearing of equal-angle steel | mm | 160×160×14 | ||

45°shearing of equal-angle steel | mm | 80×80×7 | ||

90°shearing of T-bar | mm | 160×80×14 | ||

I-beam steel | mm | 200×102×9 | ||

Channel steel | mm | 200×75×9 | ||

4 | Notch | Thickness | mm | 20 |

Width | mm | 80 | ||

Depth | mm | 100 | ||

5 | Punching hole | Max. punching thickness | mm | 20 |

Max. diameter of punching | mm | 30 | ||

Punching pressure | mm | 90 | ||

Depth of throat | mm | 355 | ||

Max. length of cylinder stroke | mm | 80 | ||

Stroke times | Times/min | 8 | ||

6 | Material strength | N/mm ² | ≤450 | |

7 | Motor power | KW | 11 | |

8 | Overall dimensions | L×W×H | 1950*900*1950 | |

9 | Net. Weight | KG | 4800 |