|

Maanshan Durmapress Machinery Technology Co., LTD

|

hydraulic sheet metal corner notcher ironworker machine

| Price: | 7000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

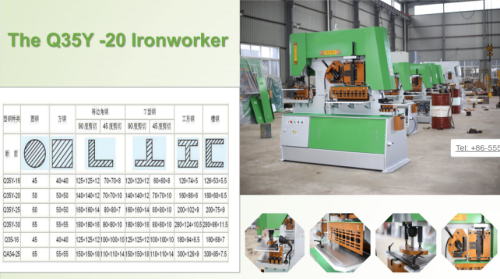

Large punching table with multi-purpose bolster

Q35Y Hydraulic Ironworker can punch and shear all kinds of material such as metal plate,

Q35Y Hydraulic Ironworker has another special function, that is, it can also bend the plate

below 500mm. With its multifunction, Q35Y Hydraulic Ironworker is your first choice among

the counterpart machine. All the components are of the highest quality in their safety,

function, capability and maintenance.

Structure and performance introduction:

This series of products are ideal equipment for cutting all kinds of angle steel, I-beam,

U-shape steel, right angle or 45 degree angle steel. Multi-workstations make it possible

to finish series operations simultaneously on one machine, such as punching,

shearing and notching, Dual-piston-type combined punching and shearing machine

allows two-man operation at the same time (stamping +another work station), German

Rexroth's integrated hydraulic valve block ensures the stability of the machine, Through

Thermal Effect of annealing processing, the entire rack is able to keep its shape forever,

without deformation. The introduction of imported brand accessories ensures the parts'

service life and use precision.

Punching: effective punching can be achieved with the machine, and stamping die is

easy to be replaced.

Bar cutting: you can quickly cut the round bar and square steel, if you want to cut U-shaped,

I-beam or T-profile section steel only by exchanging the cutting blade and the operation

procedure is very simple.

Angle cutting: you can cut several 90 ° and 45 ° angles with the help of special dies.

Metal Sheet Bending: it is very easy to fulfill the daily metal sheet bending work by making

the bending moulds.

Notching: The machine is equipped with a large-shaped slotting blade head, which can meet

your general use, as to, special shaping blade head can be customized.

Function :

Plate shearing ,section shearing,punching and V notching .Application in industries of

shipbuilding,electric power,bridge,automobiles,elevator,metal structure and other metal

fabrication field.

| Model | Q35Y-20 |

| Punching Pressure (T) | 90T |

| Max cutting thickness of steel plates (mm) | 20 |

| Material strength (N/mm²) | ≤450 |

| Angle of shear (º) | 8 |

| Flat bar shearing (T×W) (mm) | 330*20 480*10 |

| Max length of cylinder stroke (mm) | 80 |

| Trips frequency (times/min) | 8-18 |

| Depth of throat (mm) | 355 |

| Punch depth (mm) | 20 |

| Max punching diameter (mm) | 30 |

| Motor power | 5.5 |

| Overall dimensions (L×W×H)(mm) | 1950*900*1930 |

Packaging & Shipping

1 PVC film covered punching and shearing machine 2.Whole machine fixed in the container

with steel rope,very safe

3.Wooden case or pallet or iron box

4.If have stock,can provide right now

5.If no stock,small machine delivery time 7-15days.Big machine delivery time 25-40days.

6.Can give destination port best price or cost to the customer factory.

FAQ

Q1. Are you a factory or trading company?

A: We are a professional machine manufacturer.

Q2. How to choose the machine, any information I need to offer

A: the thickness, width and the material of the plate you process will be needed.

Q3. Where is your factory located? How can I visit there?

A: Our factory is located in Maanshan city Anhui Province (next to Shanghai), China.You can fly

to Shanghai airport directly. All our clients, from home or abroad, are warmly welcome to

visit us!

.jpg)

.jpg)