|

Maanshan Durmapress Machinery Technology Co., LTD

|

Hydraulic power hole puncher and metal shearing ironworker

| Price: | 9500.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The machine adopts hydraulic driver, is the latest products in our country. It can shear and cut punch a hole and cut moulds for square steel.

Founded in 2006,Maanshan Durmapress CNC Machinery Co.,Ltd is located in the Maanshan

city ,Dangtu County,close to Nanjing Airport. Our geographical position is superior and the

transportation is very convenient. Our company covers an area of 160 acres with the registered

capital of 32,000,000 Yuan. We have more than 320 employees, including all types of

engineering and technical personnel, serving the company R&D, production, and customers'

service. At the same time, we have our own sales companies in each major and medium city.

Ironworker machine iis widely used in:

1. Steel structure processing

2. Elevator car and parts processing

3. Trailer --- spare tire, trailer hinge, hook, Zhuang, tile board

4. Construction machinery industry --- belt machine, mixing station on the processing

5. Agriculture and animal husbandry machinery industry --- threshing rack body, trailer

body parts processing

6. Food industry machinery - slaughtering equipment rack and parts processing

7. High-voltage tower components processing

8. Wind power equipment --- wind power tower stairs and pedal parts processing

9. Machining --- Building embedding parts / conveyor supports and other parts processing

10. Grain Machinery --- Cereals and Oils Equipment Starch equipment bracket, shell, small

pieces of processing

11. Railway wagon / car, crane parts processing

12. Channel, square steel, bar, H steel, I-beam and other steel cutting, punching, bending

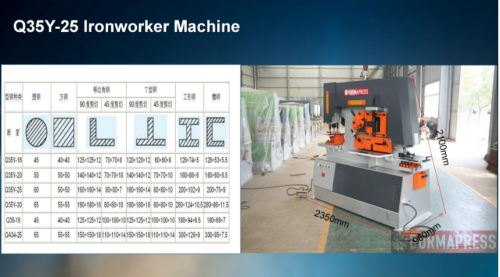

| Model | Q35Y-25 |

| Punching Pressure (T) | 120T |

| Max cutting thickness ofsteel plates (mm) | 25 |

| Material strength (N/mm²) | ≤450 |

| Angle of shear (º) | 8º |

| Flat bar shearing (T×W) (mm) | 25×330 16x600 |

| Max length of cylinder stroke (mm) | 80 |

| Trips frequency (times/min) | 8-18 |

| Depth of throat (mm) | 400 |

| Punch depth (mm) | 25 |

| Max punching diameter (mm) | 35 |

| Motor power | 11 |

| Overall dimensions (L×W×H)(mm) | 2655x960x2090 |

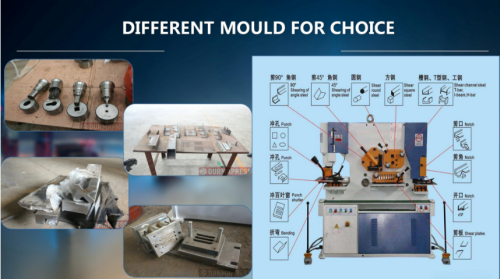

Optional tooling:

Automatic Holding System: The automatic holding system can be chosen to set up in angle

steel shearing and plate shearing work position. Additionally, the holders will fix the position

of work piece in order to save time and improve working efficiency.

Temperature cooling system: When the machine is working, you can read the temperature of

oil through the monitoring screen. If the oil temperature goes higher than 55 degree which is

the default configuration, the inside cooling system will run automatically to decrease oil

temperature in order to protect hydraulic system.

II. Main standard properties components of Ironworker:

1. All the electrical parts are IMPORT with CE certificate.

2. Professionally engineered design frame structures.

3. Steel welds with high precision strength and rigidity to eliminate vibrations.

4. Ironworker steel frame Q235 = American standard steel A306 GR55.

5. Five sets of punch and blades were installed on the machine.

6. Timer relay by Japanese OMRON.

7. All wiring terminal block by WEIDMULLER.

8. Main Electrical component by Germany Schneider.

9. Oil seals by Japanese, NOK.

10. O-Ring and Valve by Taiwan for piston pump more durable.

11. Hydraulic System by Japanese Yuken.

12. Motor by SIMENS Germany

13. Hydraulic fuel tanks and ironworker frame built by our Factory.

14. Dual independent hydraulic cylinder

15. Dual Footswitch controlled work separately

16. Easy Adjustable stroke control with ruler

17. Indicator on both hydraulic cylinders

18. Electric back gauge auto stop

1.we put the machines on the different type container by steel wire and and all of the machines

is by plastic film

2.For small equipment we use the wooden package to protect that

Quality assurance:

1.Company organizes the production as per ISO9001:2008 standard. From design control,

process control, inspection control to delivery, installed and service, the whole process

control. The running of quality system performs quality manual, procedure files, work

instruction and related technical and management standard together with standard and

regulation layout by company strictly. Quality system realizes whole screw and whole

procedure control completely.

2. Quality assurance procedure for important out-source parts.

a. Mainly out-sourced parts: control system, cylinder, hydraulic components, motor, pump etc.

b. After evaluation, select qualified suppliers as business partners.

c. Purchasing according to plan, purchase contract, quality requirement, technical standard

and inspection standard.

3.Receiving inspection on site either in supplier or our company with related technicians.

Packaging & Shipping

1 PVC film covered punching and shearing machine 2.Whole machine fixed in the container with steel rope,very safe

3.Wooden case or pallet or iron box

4.If have stock,can provide right now

5.If no stock,small machine delivery time 7-15days.Big machine delivery time 25-40days.

6.Can give destination port best price or cost to the customer factory.

Our Services

1.All machines have been tested by 48 hours before ship out.

2.All products have 2 year warranty.

3.Supported 24 hours online service. If any problems happen, our team will do our best to solve the problems.

4.If any component is damaged during guarantee time. we can send the component to the customer by DHL freely.

FAQ

Q1. Are you a factory or trading company?

A: We are a professional machine manufacturer.

Q2. How to choose the machine, any information I need to offer?

A: the thickness, width and the material of the plate you process will be needed.

Q3. Where is your factory located? How can I visit there?

A: Our factory is located in Maanshan city Anhui Province (next to Shanghai), China.You

can fly to Shanghai airport directly. All our clients, from home or abroad, are warmly welcome to visit us!

.jpg)

.jpg)