|

Maanshan Durmapress Machinery Technology Co., LTD

|

Hvac duct production line Auto line air duct manufacturing machines

| Price: | 26000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

We assist customers in well understanding the product information like features, functions and applications and so on. As for the detailed procuring information or drawings, our professionals will first conduct a careful examination and then recommend the most suitable machines or devise proper schemes for customers. We also provide free samples if necessary.

Service during the Sale

1. We are manned with professional salesmen and technicians to provide the information, technical support and the optimal solutions with high cost performance.

2. Based on the specific requirements of customers and the lead time, we will formulate a rigorous operation process. Through the close cooperation of Commodity Department, Sales Department, Technical Department and the Ocean Shipping Department, we are devoted to timely supplying customers with superior machines.

3. Generally, certain quantity of quick-wear parts will be delivered with the goods. The delivery deadline depends on the specific order, which is usually within 1 to 3 months.

After-Sale Service

1. One year warranty is provided.

2. Customers can send photos or samples for our confirmation once the parts are damaged within the one year warranty. If the parts are not damaged by misoperation , we will reply to customers within 48 hours and provide free parts for replacement. Besides, for the parts out of commission and beyond the

warranty, we only charge for the basic costs of parts.

3. We regularly follow up the service condition of products, and timely analyze and copy with the feedbacks. As for the disputes, we will figure out effective actions to reach mutual satisfaction.

Function

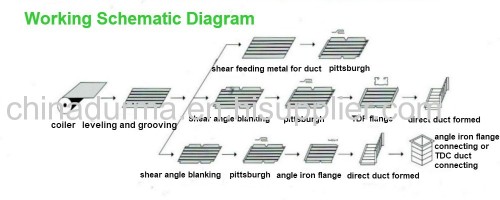

Duct manufacture auto line 5 is mainly for TDF flange/ angle steel flange/ C-cleat flange forming and its daily production capacity is 600-2000 square meters. Only with inputing the dimension you need on the LCD, then the auto line will automatically complete uncoiling, leveling, grooving, punching, shearing, locking, TDF flange/ angle steel flange/ C-cleat flange forming and folding into rectangular ducts.

Features:

1.The linear structure of machine makes processing smoothly occupies a small space.

2.All the rolling reels are made of bearingsteel so that the lifetime prolongs by more than 5 times.

3. Under the material-saving mode of CNC system, waste is less than 20mm per roll.

4.The locating system is very accurate with servo feeding machanism, especially when processing square-shaped pipes.

5.It's equipped with 10 inch LCD touch screen and optional dual keyboard mode to keep operation stable.

6.It requires at least one person to operate and each shift can output 600-2000.

7.With production memory functions, the production orders can be tracked and checked.

Main Import Configuration | Basic Configuration |

1.Cylinder imported from Germany Festo | 1.Two electric coil cradles,4 material trays(5-7t each roll) |

2.Beijing Huade + hydraulic system from Taiwa | 2.One rack |

3.Japan Omron encoder | 3.One host(line 2 host) |

4.Taiwan Hiwin linear guideways | 4.One mechanical arm clutching,locating and transferring platform |

5.Taiwan Delta CNC system | 5.One displacement type locking machine |

6.One duplex TDF flange forming machine | |

7.One duplex angle steel flange forming machine | |

8.One servo feeding platform | |

9.One hydraulic folding machine | |

10.One set of computer controlling system |

Basic equipment:

1.Two electric coil candles(3000*1900*950 mm x 2), 4 material trays (5-7t per roll) |

2. A material supporting frame |

3.A host, including leveling, grooving, punching and cutting (also named auto line II) |

4.A displacement type Pittsburgh locking machine |

5.A electric feeding and transferring platform |

6. A duplex TDF flange forming machine |

7. A duplex angle steel flange forming machine |

8. A Servo feeding plat |

9. A hydraulic folding machine |

10.A computer controlling system and a set of production software |

Main import Configuration: |

1. Cylinder imported from Germany Festo |

2. Beijing Huade or hydraulic system from Taiwan |

3. Japan Omron encoder |

4. Taiwan Hiwin linear guideways |

5. Schneider electrical system |

Technical parameter:

Model | Max Coil Width (mm) | Thickness Range (mm) | Speed (m/min) | Power (kw) | Dimension (m) | Shearing Tolerance (mm) | Diagonal Tolerance (mm) | Weight (t) |

CAL5-1.2 x 1300 | 1300 | 0.4-1.2 | 0-18 | 36 | 24*2.8*1.5 | ±0.5 | ±0.5 | 12 |

CAL5-1.2 x 1600 | 1600 | 0.4-1.2 | 0-18 | 36 | 24*3.2*1.5 | ±0.5 | ±0.5 | 12.5

|

| Model | Thickness range (mm) | Width (mm) | Max-working speed (m/min) | Coiler weight (kg) | Weight (kg) | Dimension (mm) |

| SDL-V | 0.5-1.2 | 1300 | 16 | 6000*4 | 9500 | 24000*3500*1300 |

| 1600 | 10000 | 24000*3800*1300 | ||||

| Note:The weight and size of two feeding shelf are not included. Customers can order the line with different sheetspecifications, width and coiler weight. | ||||||

Due to continuous product improvement, where there is actual samples technical data and product data inconsistency, it shall be subject to the actual machine, without notice.

FUNCTION

It's mainly for TDF/angle steel/C-shaped flange forming with daily processing capability of 1000-2500 square meters. Only with inputting dimensions in duct, production line can automatically complete uncoiling , leveling, beading, punching, shearing, locking, forming TDF/angle steel/C- shaped flange and folding.

PERFORMANCE FEATURES

1. The machine is U-shaped,easy to install and it's suitable for small-sized or mid-sized work-shops because it occupies a small piece

2. The injection holes are used at both ends of the drive shaft, to enhance the bearing life.

3. Power bending function is used to prevent generating the waste and make sure perfect bending accuracy.

4.It only takes 20-25 seconds to make one L-shaped workpiece and the efficiency will double comparing with the linear type.

5.Without moving back and forth the fixed locking machine is able to improve the efficiency.

6.All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

7. Under the material-saving mode of CNC system, waste is less than 20mm per roll.

8.With production memory functions, the production orders can be tracked and checked.

Main Import Confuguration

1. Beijing Huade Plus hydraulic system from Taiwan

2. Japan Omron encoder

3. Taiwan Hiwin linear guideways

4. Schneider electrical system

Basic Configuration

1.Two electric coil cradles, 4 material trays ( 5-7t each roll)

2.One rack

3.One host ( line 2 host)

4.Two stainless steel roller conveyer platforms

5.One fixed joint locking machine

6.One duplex TDF flange forming machine

7.One duplex angle steel flange forming machine

8.One servo feeding platform

9.One hydraulic foldingmachine

10.One set of computer controlling system

Customer Visiting

Our service :

We assist customers in well understanding the product information like features, functions and applications and so on. As for the detailed procuring information or drawings, our professionals will first conduct a careful examination and then recommend the most suitable machines or devise proper schemes for customers. We also provide free samples if necessary.

Service during the Sale

1. We are manned with professional salesmen and technicians to provide the information, technical support and the optimal solutions with high cost performance.

2. Based on the specific requirements of customers and the lead time, we will formulate a rigorous operation process. Through the close cooperation of Commodity Department, Sales Department, Technical Department and the Ocean Shipping Department, we are devoted to timely supplying customers with superior machines.

3. Generally, certain quantity of quick-wear parts will be delivered with the goods. The delivery deadline depends on the specific order, which is usually within 1 to 3 months.

After-Sale Service

1. One year warranty is provided.

2. Customers can send photos or samples for our confirmation once the parts are damaged within the one year warranty. If the parts are not damaged by misoperation , we will reply to customers within 48 hours and provide free parts for replacement. Besides, for the parts out of commission and beyond the

warranty, we only charge for the basic costs of parts.

3. We regularly follow up the service condition of products, and timely analyze and copy with the feedbacks. As for the disputes, we will figure out effective actions to reach mutual satisfaction.

Company Information

FAQ:

1.How about your QC12Y Hydraulic Swing shearing machine quality?

Durmapress is a mature brand in CHINA,through our many years research in technology. our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Better machines.

2. What's your after-sale service?

Better provide oriented after-sales service including the oversea engineers training available and also international dealer center for any emergency guidance.We have established worldwide network to guarantee our timely response for your any demand no matter where are you.

We welcome engineers from your side to learn the technical design and normal maintenance here,this will help your easy in understanding and helpful if you need to be our dealer.

3. How to operate your QC12Y Hydraulic Swing shearing machine?

Don't worry,we have our company own CD/Manual to show you along with the machine.So you can learn this from the existing documents to deepen your knowledge and understanding. Anyhow there are another way is through internet video face to face for machine teaching, because of the high development in internet,the world has become smaller and you can easy catch us if any assistance needed.

.jpg)

.jpg)