|

Maanshan Durmapress Machinery Technology Co., LTD

|

Production Line III Aluminum Flexible Air Duct Machine

| Price: | 25000.0 USD |

| Payment Terms: | T/T,L/C,D/A,WU,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

Mananshan Durmapress Machinery Technology Co., Ltd >>>

Our company founded in 1990s is a fixed-point company of Ministry of Construction of China, we are engaging in construction machinery researching, development and manufacturing. Our main products are JZM series electric rolling drum concrete mixers, JS Series Double shaft concrete

mixer,JZR series diesel engine concrete mixers, PLD series aggregate batching and dispensing machines, LSY series cement screw conveyors and HZS/HLS series concrete mixing and batching plant. All these products have won great favor and popularity with more and more customers in

domestic and oversea markets.

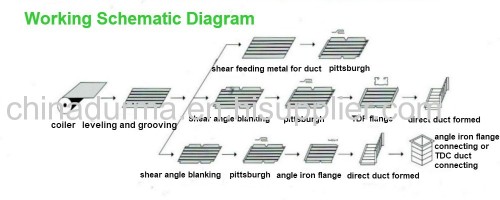

Product Introduction Of good price duct machine

DURMAPRESS good price duct machine is composed of feeding rack, leveling beading machine, hydraulic shear angle machine, hydraulic plate shear,displacement type combined locking machine,manipulator hand material positioning and conveying platform, duples TDF flange machine and duples angle steel flange machine, servo feeding platform, pneumatic folding square machine, electric control part adopts full computer control, bending servo feeding, positioning precision, especially in the processing of square pipe, guarantee the precision of bending, its maximum feed speed is 16m/min, the length of error is plus or minus 0.5mm,this line can be processing TDF flange and angle steel flange duct,exchange is simple and rapid.

The features of this machine are covers a small area, linear processing, high production efficiency, it can make a small section of the square duct. TDF flange duct with minimum cross section of 200*200 mm

Performance Features Of good price duct machine

1.The linear structure of machine makes processing smoothly occupies a small space.

2.All the rolling reels are made of bearingsteel so that the lifetime prolongs by more than 5 times.

3. Under the material-saving mode of CNC system, waste is less than 20mm per roll.

4.The locating system is very accurate with servo feeding machanism, especially when processing square-shaped pipes.

5.It's equipped with 10 inch LCD touch screen and optional dual keyboard mode to keep operation stable.

6.It requires at least one person to operate and each shift can output 600-2000.

7.With production memory functions, the production orders can be tracked and checked.

Main Import Configuration | Basic Configuration |

1.Cylinder imported from Germany Festo | 1.Two electric coil cradles,4 material trays(5-7t each roll) |

2.Beijing Huade + hydraulic system from Taiwa | 2.One rack |

3.Japan Omron encoder | 3.One host(line 2 host) |

4.Taiwan Hiwin linear guideways | 4.One mechanical arm clutching,locating and transferring platform |

5.Taiwan Delta CNC system | 5.One displacement type locking machine |

6.One duplex TDF flange forming machine | |

7.One duplex angle steel flange forming machine | |

8.One servo feeding platform | |

9.One hydraulic folding machine | |

10.One set of computer controlling system |

Main import Configuration | |||

1. Cylinder imported from Germany Festo | |||

2. Beijing Huade or hydraulic system from Taiwan | |||

3. Japan Omron encoder | |||

4. Taiwan Hiwin linear guideways | |||

5. Taiwan Delta CNC system |

Basic Configuration | |||

1. Two electric coil cradles, 4 material trays (5-7t each roll) | |||

2. One rack | |||

3. One host (line 3 host) | |||

4. One mechanical arm clutching, locating and transferring platform | |||

5. One displacement type locking machine | |||

6. One duplex TDF flange forming machine | |||

7. One duplex angle steel flange forming machine | |||

8 One set of computer controlling system |

| Model | Thickness range (mm) | Width (mm) | Max-working speed (m/min) | Coiler weight (kg) | Weight (kg) | Dimension (mm) |

| SDL-V | 0.5-1.2 | 1300 | 16 | 6000*4 | 9500 | 24000*3500*1300 |

| 1600 | 10000 | 24000*3800*1300 | ||||

| Note:The weight and size of two feeding shelf are not included. Customers can order the line with different sheet specifications, width and coiler weight. | ||||||

Due to continuous product improvement, where there is actual samples technical data and product data inconsistency, it shall be subject to the actual machine, without notice.

Our service:

| 5. Maintenance after sale |

| 1. This product's warranty period is one year. |

| 2. If users modify machine without permission of our technology department, and get the machine damaged, we are not responsible to maintain the machine for free. |

| 3. In the warranty period, if the machine get damaged because users operate it improperly, materials expenses will be required. |

| 4. After warranty period, we will continue to offer technical assistance. |

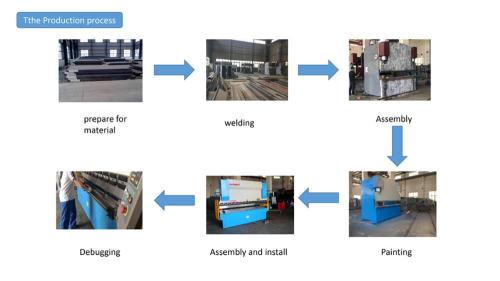

Package & shipping

6. Packaging and shippingPackaging Detail: standard exporting package or depend on customers' demand.1 packaged in plasticfilm.2 pallet or wood box.3 ground fixed bolt to confirm steady and avoid damage.4 tightly belf to fasten machine in container.Delivry Detail: normally within 30 days after receive deposit.

.jpg)

.jpg)