|

Maanshan Durmapress Machinery Technology Co., LTD

|

U shape auto air duct manufacturing line machines

| Price: | 25000.0 USD |

| Payment Terms: | T/T,L/C,D/A,WU,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

durmapress's is a comprehensive enterprise dealing economic and technology cooperation that specializes in manufacturing for metal fabrications and distributing of all types of machinery tools Including Industrial Equipment, fabricating equipment, sheet metal equipment and production line machinery.

We are not only trading with customers from domestic and oversea but also providing customers with technical, commutation and after sales support.

Our dedication to the highest quality products and services have establish excellent trade relations with customers from all over the world. EMM's team memebers includes qualified sales specialists and highly trained technical professional to help provide quick service and the best quality of work in order to meet our cust

Product Introduction Of good price duct machine

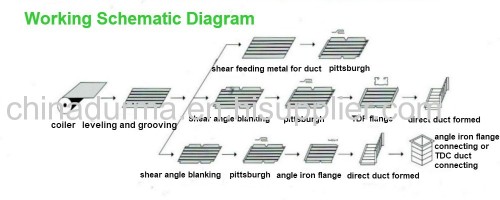

DURMAPRESS good price duct machine is composed of feeding rack, leveling beading machine, hydraulic shear angle machine, hydraulic plate shear,displacement type combined locking machine,manipulator hand material positioning and conveying platform, duples TDF flange machine and duples angle steel flange machine, servo feeding platform, pneumatic folding square machine, electric control part adopts full computer control, bending servo feeding, positioning precision, especially in the processing of square pipe, guarantee the precision of bending, its maximum feed speed is 16m/min, the length of error is plus or minus 0.5mm,this line can be processing TDF flange and angle steel flange duct,exchange is simple and rapid.

The features of this machine are covers a small area, linear processing, high production efficiency, it can make a small section of the square duct. TDF flange duct with minimum cross section of 200*200 mm

Performance Features Of good price duct machine

1.The linear structure of machine makes processing smoothly occupies a small space.

2.All the rolling reels are made of bearingsteel so that the lifetime prolongs by more than 5 times.

3. Under the material-saving mode of CNC system, waste is less than 20mm per roll.

4.The locating system is very accurate with servo feeding machanism, especially when processing square-shaped pipes.

5.It's equipped with 10 inch LCD touch screen and optional dual keyboard mode to keep operation stable.

6.It requires at least one person to operate and each shift can output 600-2000.

7.With production memory functions, the production orders can be tracked and checked.

Main Import Configuration | Basic Configuration |

1.Cylinder imported from Germany Festo | 1.Two electric coil cradles,4 material trays(5-7t each roll) |

2.Beijing Huade + hydraulic system from Taiwa | 2.One rack |

3.Japan Omron encoder | 3.One host(line 2 host) |

4.Taiwan Hiwin linear guideways | 4.One mechanical arm clutching,locating and transferring platform |

5.Taiwan Delta CNC system | 5.One displacement type locking machine |

6.One duplex TDF flange forming machine | |

7.One duplex angle steel flange forming machine | |

8.One servo feeding platform | |

9.One hydraulic folding machine | |

10.One set of computer controlling system |

Main import Configuration | |||

1. Cylinder imported from Germany Festo | |||

2. Beijing Huade or hydraulic system from Taiwan | |||

3. Japan Omron encoder | |||

4. Taiwan Hiwin linear guideways | |||

5. Taiwan Delta CNC system |

Basic Configuration | |||

1. Two electric coil cradles, 4 material trays (5-7t each roll) | |||

2. One rack | |||

3. One host (line 3 host) | |||

4. One mechanical arm clutching, locating and transferring platform | |||

5. One displacement type locking machine | |||

6. One duplex TDF flange forming machine | |||

7. One duplex angle steel flange forming machine | |||

8 One set of computer controlling system |

| Model | Thickness range (mm) | Width (mm) | Max-working speed (m/min) | Coiler weight (kg) | Weight (kg) | Dimension (mm) |

| SDL-V | 0.5-1.2 | 1300 | 16 | 6000*4 | 9500 | 24000*3500*1300 |

| 1600 | 10000 | 24000*3800*1300 | ||||

| Note:The weight and size of two feeding shelf are not included. Customers can order the line with different sheet specifications, width and coiler weight. | ||||||

Due to continuous product improvement, where there is actual samples technical data and product data inconsistency, it shall be subject to the actual machine, without notice.

Our service

1.Installation Service

We dispatch technician to customer's factory for installation and preparation of machine operation. ( Customers only need to pay for the air fare and hotel .)

2.Training Service

Our technicians are available to your factory and provide training on how to use the machine. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the air fare and hotel. )

3.Quality Guarantee

We arrange final test before shipment. After making sure machine is in the best condition, we make shipment.

Machine warranty is 5 years.

Packing & shipping

RFQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

.jpg)

.jpg)