|

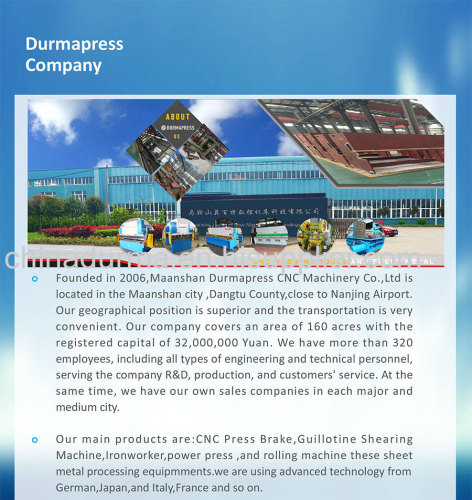

Maanshan Durmapress Machinery Technology Co., LTD

|

cnc press brake machine

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Press Brake

Raw Material:

Sheet / Plate Rolling

Material / Metal Processed:

Stainless Steel

Power:

Cnc

Automation:

Automatic

Product Description

Properties and characters : hydraulic plate press brake, cnc hydraulic plate press brake machine

1.steel welded structure, stress elimination by vibration, high mechanical strength, and exceptional rigidity;

2. hydraulic top-drive, steady and reliable;

3.mechanical stop for maintaining synchronization and high precision;

4.electric adjustment, manual fine adjustment, and digital display for back stop distance and up sliding stroke.

Functions:

This machine is high-efficiency and high-precision in bending sheet metal. Using different kinds of upper and

lower dies can bend all kinds of work pieces. One slider travel makes a sheet bending and the complicated shape

work piece may be achieved through bending many times.

Overall structure: hydraulic plate press brake, cnc hydraulic plate press brake machine

5.1 Using UG (finite element) analysis, through computer aid design, with nice appearance.

5.2 The machine structure is welded with steel plate, with sufficient strength and rigidity.

The hydraulic drive prevents the machine from serious overload operation accidents caused

by the change of sheet thickness or bad choice of lower die cavity. Additionally, this machine

is also featured by the steadiness of work, convenience of operation, and reliable safety.

5.3 The mechanic block is equipped in the oil cylinder to ensure the fixing accuracy when the

slider travels to the bottom dead point and so as to assure the consistency of bending angle in bulking production.

5.4 Using German technology to eliminate internal stress.

5.5 Entire frame using striking grit to get rid of rust and spout anticorrosive paint.

Working slider structure: hydraulic plate press brake, cnc hydraulic plate press brake machine

6.1 The machine is equipped with hydraulic electric control, freely adjustable slider travels and inching,

semi-automatic, automatic operating criterion convenient for module trial and adjustment.

6.2 .Up-move type bending design,pair oil cylinders working simultaneously, balanced operation,convenient and safety.

Electrical control system: hydraulic plate press brake, cnc hydraulic plate press brake machine

7.1 Electric components and material are accord with international standard, safety and reliable, long life, and strong ant

jamming capability.

7.2 Moving footpad attached.

7.3 Choosing high grade famous electrical control components.

7.4 The power of the machine is 3-phase and 4-line AC380V, control loop is AC220V.

7.5 Main power way of motor has short circuit,over load,lack phase protection.

7.6 Operation buttons equipped on machine button stage, electric switch,pilot lamp equipped in electric box

.

7.7 Oil pump stop button as the total button of machine, when oil pump power off, whole machine stops working.

7.8 Inching control button and emergency stop button are installed on machine.

8) The synchronization of the slider travel of bending machine is mechanic synchronous unit in simple, stable and reliable

structure with synchronous precision required by this machine. And generally, it can be used for long time while don't need

to be repaired frequently.

Back stopper: hydraulic plate press brake, cnc hydraulic plate press brake machine

The adjustment of back stopper is droving by 0.55KW motor, drove by synchronous belt with precision ball bearing lead

screw. With high driving precision and exact calculating.

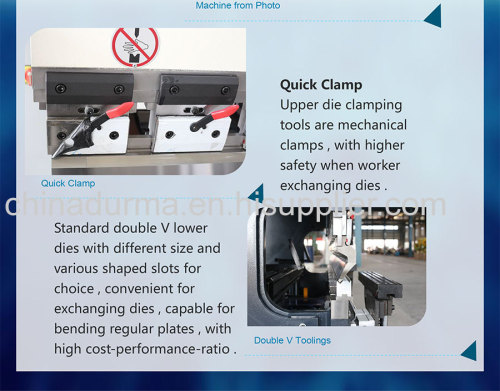

Punch and die: hydraulic plate press brake, cnc hydraulic plate press brake machine

1. A set of upper and lower die attached with machine.

2. Normally, the short moulds in sectional form are used to splice for desired length with high precision, fine interchangeability,

and convenience for dismantling and installation. In particular, the connecting section to the upper die is equipped with wedge-shape

regulating unit, which, as compensation, may raise the work precision of work pieces in full length.

3. The lower dies are processed in different V-gutters to make operators select conveniently and it is equipped with lower die standing

up structure, only need to put lifting roller chain on the slide lifting ear and lower die lifting ear, loose top formwork to raise slider to

turn lower die then to select the location surface of V-gutter.

The detail pictures: hydraul

FAQ

press brake;

Payment terms, Usually is T/T 30% deposit in advance,70% balance before delivery.

Warranty time,24 months after sale.

After sale service,providing technical service,replacing the parts freely during warranty not include artificial

damage or damage caused bt improper operation,we can send our engineer to your country if necessary.

Machine moulds and dies can be designed according to customers needs.

ic plate press brake, cnc hydraulic plate press brake machine

.jpg)

.jpg)