|

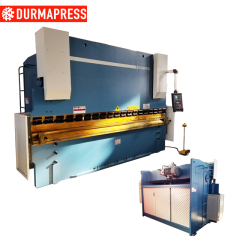

Maanshan Durmapress Machinery Technology Co., LTD

|

cnc metal sheet press brake

| Qty (Set/Sets) | Unit Price (7900.0~8000.0 USD) |

| 1 | 8000 |

| 2 + | 7900 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Complete working cycle can be realized through the control of hydraulic valve.

Product Description

Features:

1.All Steel Welded, Vibration eliminate stress, high mechanical intensity, good rigidity.Hydraulic upper transmission, steady and reliable.

2. Mechanical stop dog, synchronization in twist axis, high precision.

3.Back gauge distance, upper ram stroke can be adjusted by motor-drive,manual operation micro-adjust equipment, numerical display.

4.WE WORKTABLE full deflection compensation

Basic Main Components

1.NC display: Korea

2 Main Seal: PARKER

3.Main electronic element: Siemens/Schneider

4 Main Motor

5 Group valev

6.Conjugate internal gear pump

7.Back gauge

8.Mould

9.Oil cylinder

10.Front Plate Feeding will be equipped

11.Free charge Standard Upper and Down Mould

Main Character and Function

All the components of the machine are designed under the instruction of the Computer aided design and software of CAD/CAE/CAM to fully guarantee the intensity and rigidity of all the components.

The whole body under total wielded, thickness and reliable in machine body with high-rigidity and good in shock absorption reduction.

The machine structure are composed by body frame, working table, slide block, main cylinder and backgauge.The advantage design and produce style can ensure the machine usage and high precision.The main produce procedure as below(all process under strictly inspection)

Plate stock----physical and chemical inspection----Plate Pre-treatment (Rust-Cleaning) --- CNC flame Cutting-- Cutting the welded joint----Group Welding----Gas Shielded Welding---Ageing treatment----Milling Planer working----The Assembly of finished products

The machine body, Slide Block, Working table and other main components are under one time clamping of large landing boring and milling machine to ensure several geometric accuracy of the main machine.

The machine is greatly enhanced in anti-torque and electronic load resistance. Machine can normally work in full loaded situation. Working table, Upright Column, Crossbeam and Ram are good and high in design rigidity. Little deformation between the working table and ram when work to guarantee good straightness and uniformity in angle.

Machine's main components under guaranteed quality or trustable company

The motor and electronic system elements are all composed from Siemens or Schneider

Dies can be designed under clients' requirement.

Oil pump can be used from China chengjie enterprise who is used in China's Aircraft industry.Or we can use Germany ECKERLER enterprises.

The seal will be from USA Parker or Japan Valqua company.

The hydraulic system and valve optional Germany BOSCH company.

The security protection equipment: We equipped protect fence to avoid any penetration inside and foot controller with emergency control button

| Nominal force | 630KN |

| Worktable length | 2500mm |

| Poles distance | 1900mm |

| Throat depth | 250mm |

| Stroke | 100mm |

| Max open | 320mm |

| Power | 5.5KW |

| Dimension | 2500*1300*2210 |

| stanless steel | 1.5mm |

MAIN TECHNICAL SPECIFICATION

1. Size: 2200mm × 1500mm × 1700mm

2. total weight: about1800KG

3. controlling system: PLC

4. power: 2.2KW

5. working speed:10--12m/min(adjustable)

6.Control: PLC computer control ( frequency converter)

Detailed Images

Front suport and clamps

Front support on liner guide can move left and right easily, up and down by manual.

Upper die quick clamp with compensation device.

Main motor

Siemens brand from Germany

Optional for ABB or WNN.

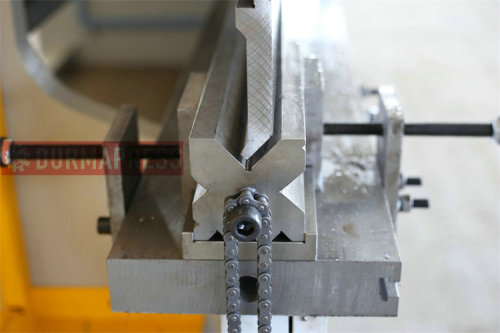

Tooling and C-gap

Machine with one set standard toolings with upper punch segmented and multi-V die in one pc.

C-throat gap high strength.

Back gauge

High precistion stop finger with mutli axes backgauge

servo motor drived with high speed.

Optional Machine Parts

World good controller, CNC X, Y1,Y2 axis Control.

Certifications

CUSTOMER VISIT

Our Service

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience and can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the production is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting and damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country for installation and commissioning Buyer pays each engineer 100USD / Day besides the round-tickets, room and board.

OUR TEAM

DURMA SUCCESSFUL CASE

DURMA OFFICE

Packing & Delivery

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

.jpg)

.jpg)