|

Maanshan Durmapress Machinery Technology Co., LTD

|

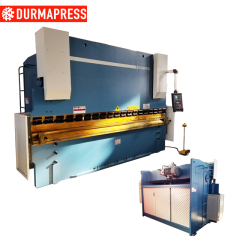

CNC hydraulic Press brake with 4 axis

| Price: | 10300.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67Y

Machine Type:

Press Brake

Raw Material:

Steel /Metal/ Plate

Material / Metal Processed:

Alloy, Stainless Steel, Mild Steel, Carbon Steel,

WC67Y Hydraulic Press Brake

The press brake machine is a kind of machine capable of bending the thin plate. The structure mainly comprises a bracket, a worktable and a clamping plate, the worktable is arranged on the bracket, the workbench is composed of a base and a pressure plate, the base is connected with the clamping plate The base is composed of a seat shell, a coil and a cover plate. The coil is arranged in the depression of the seat shell, and the top of the depression is covered with a cover plate. The coil is energized by the conducting wire when in use, and the gravitation force is generated on the pressure plate after electrification, thereby achieving the clamping of the sheet between the pressure plate and the base. As a result of the use of electromagnetic force clamping, making the platen can be made of a variety of workpiece requirements, but also to have the workpiece sidewall processing, the operation is also very simple.

1. Main Configuration

Estun E21 controller

Controller controls and adjusts Y-axis and X-axis

Servo drive and control positioning of X-axis and Y-axis

Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

Front Finger protection ( safety light curtain )

South Korea KACON pedal switch ( safety grade 4 )

Back metal safeguard, CE standard

Safety relay monitor pedal switch, safety protection

Safety standard ( 2006/42/EC)

2. Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

3.ESTUN E21 Controller

Back gauge and block control

Control for general AC motors,frequency inverter;

Intelligent positioning;

Stock counter;

Holding/decompression time setting;

Program memory of up too 40 programs up to 25 steps per program;

Chinese and English menu operation;

One side positioning;

Retract function;

One key backup / restore of parameters

mm / Inch

Export to more than 60 countries

The container to our factory directly,we fixed the machines by ourselves

All the machines will be bought the insurance before shipping

We will provide the installation and operation of the machine to you after delivery

Our Service

1.Installation Service

We dispatch technician to customer's factory for installation and preoperation of machines. (Customers only need to pay for the airfare and hotel expense.)

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the airfare and hotel expense.)

3.Quality Guarantee

We arrange a final test before shipment. We will make shipments after making sure machine is in the best performance.Machine warranty is 2 years.

RFQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

.jpg)

.jpg)