|

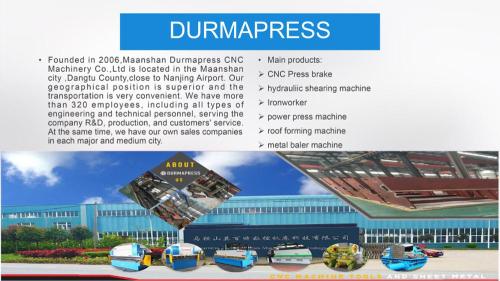

Maanshan Durmapress Machinery Technology Co., LTD

|

CE approved Cnc sheet metal slotting machine

| Qty (Set/Sets) | Unit Price (37000.0~37100.0 USD) |

| 1 | 37100 |

| 2 + | 37000 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front

Our Company

Product Description

The first class groover machine in the world(export Japan,Holland,Canada,Singapore,Thailand,Vietnam,Pakistan,Lebanon and other countries)

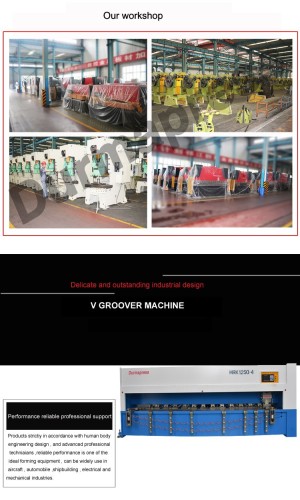

AHK CNC sheet metal V groover machine(high speed percision servo drive)

Main feature and special function

1.Bevelling available ;

2.Available to groove not from one side of plate an end not at another side;

3.The minimum distance from the side of plate to the first groove line is 10-12mm;

4.The minimum size of plate to groove is 100x100mm;

5.Grooving from one point to another point

6.Power saving;

7.Environmental protection (without hydraulic oil)

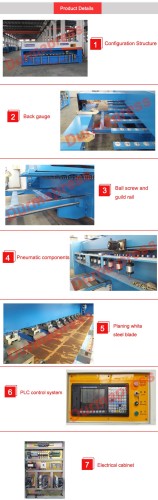

Main Device

| High precision ball screw | Taiwan TBI |

| Precision linear guide rail | Taiwan HIWIN |

| Angular contact ball bearings | NSK of Japan |

| Planing white steel blade | SECO of Sweden |

| Servo motor | Yaskawa of Japan |

| PLC | Yaskawa of Japan |

| Electrical components | Schneider of France |

| Power cable | IGUS of Germany |

| Pneumatic components | Taiwan AIRTAC |

Main parameters

| Name | 4Ax4000mm | 6Ax6000mm |

| Processing Width | 850-1500mm | 850-1500mm |

| Processing Length | 4000mm | 6000mm |

| Processing Thickness | 0.5-6mm | 0.5-6mm |

| The back and front moving distance of beam | 850-1500mm | 850-1500mm |

| Moving speed of beam | 50-5000mm/min | 50-5000/min |

| The maximum left and right moving distance of carriage | 4300mm | 4300mm |

| The maximun moving speed of carriage | 50mm/min | 50mm/min |

| Deviation of length | ±0.05mm | ±0.05mm |

| Location percision | ±0.05mm | ±0.05mm |

| The maximum travel of knife rest | 100mm | 100mm |

| Machine size | 5900*2050*2300 | |

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Packaging Details

1.Our wooden case is after fumigation treatment.Needn't timber inspection,saving shipping time.

2.All the spare parts of the machine were covered by soms softmaterials,mainly using pearl wool.

3.The outmost is wooben case with fixed formwork.

FAQ

Check below for more information on placing an order

1. Inquiry-Professional quotation.

2. Confirm the price, lead time, type, payment term etc.

3. OHA sales send the Proforma Invoice with DURMAPRESS seal.

4. Customers make the payment for deposit and send us Bank receipt.

5. Initial Production Stage-Inform the clients that we have got the payment, and will make the according to your request or our standard, we inform that we will arrange the production & inform the estimated time.

6. Middle Production-send photos to show the production line which you can see your products in. Confirm the estimated delivery time again.

7. End Production-Mass production products photos will send to you for approval. You can also arrange the third party Inspection.

8. Clients make payment for balance and OHA ship the goods. Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients.

9. Order can be say "finish" when you receive the goods and satisfy with them.

10. Feedback to DURMAPRESS about Quality, Service, Market Feedback & Suggestion. And we can do better.

Our Service

1). Quality assurance system

Company organizes the production as per ISO9001:2008 standard. From design control, process control, inspection control to delivery, installed and service, the whole process control. The running of quality system performs quality manual, procedure files, work instruction and related technical and management standard together with standard and regulation layout by company strictly. Quality system realizes whole screw and whole procedure control completely.

2). Quality assurance procedure for important out-source parts.

a. Mainly out-sourced parts: control system, cylinder, hydraulic components, motor, pump etc.

b. After evaluation, select qualified suppliers as business partners.

c. Purchasing according to plan, purchase contract, quality requirement, technical standard and inspection standard.

d. Receiving inspection on site either in supplier or our company with related technicians.

MACHINE QUALITY

Machine design and manufacture performs occupation standard and comply with the requirement of quality, specification and characters herein this technical regulation.

Guarantee period start from the day the machine acceptance report signing. Period would be one year.

Technical documents which supplier in charge of furnish and handed to use should be consist with technical regulation, and throughout technical, technics, produce, installation and setting

After-sale-service

Manufacturer will in charge of the technical service for the whole using life of the machine.

If you want to know moe about the machine ,pls. contact with us freely.

.jpg)

.jpg)