|

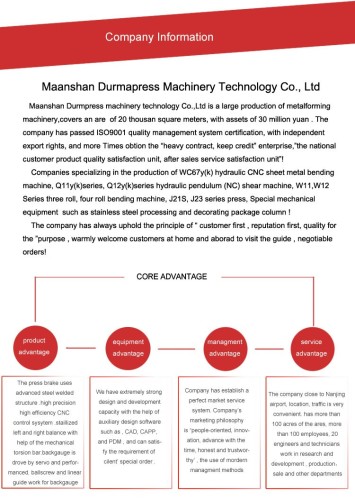

Maanshan Durmapress Machinery Technology Co., LTD

|

Sheet Metal CNC Slot Machine For Decoration

| Price: | 33900.0 USD |

| Payment Terms: | T/T,L/C,D/P,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

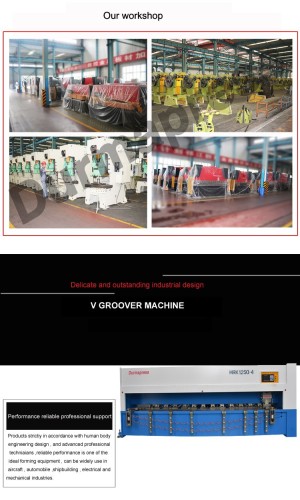

Ma'anshan Durmapress Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

Advantages: conventional machine is clamps hold the sheet metal moving over the working table, so the sheet surface is very easy to be scratched.

Now this machine's biggest advantage is sheet metal fixed, has no relative motion. the work piece is protected perfectly, especially for use in mirror stainless steel plates on decoration, and so that the machine has a high processing speed.

Hydraulic v grooving machine

Work:

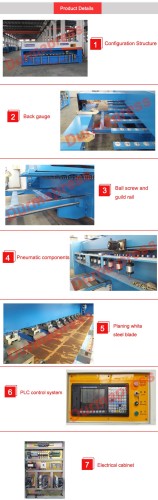

Numerical control systems, slot machine adopts PLC + touch screen CNC system

Transmission parts

Press apparatus

Efficient:

Frame structure with the overall table, mobile gantry beam also welded frame structure, the implementation of the overall welding, tempering after welding the whole, all to ensure the overall good rigidity, have to ensure that the future use is not deformed.

Overall table frame fixed and mobile gantry beam for cutting slotting, grooving speed frequency control, smooth and efficient cutting process, the cutting surface quality is good.

A color touch screen controller adopts special software, Chinese / English operation menu, simple and straightforward. Manual, automatic two working modes to choose from, fully meet the various processing requirements. Man-machine dialogue interface, easy to learn and operate, convenient processing size input, process real-time display, error alarm will automatically

Machine is 4 axes control, the X-axis, Y1 axis, Y2 axis, Z axis. high positioning accuracy, where Y1, Y2 through the PLC synchronization system, guaranteed to always synchronized. X-axis is with inverter controlled AC gear motor. HIWIN brand high precision ball screw, helical rack and pinion driven sound small and precision.

Alone the working table, there is hydraulic clamps. According to different material or thickness, clamping force can be adjusted.

1), the machine uses three alloy knife while processing methods, thus cutting is more evenly, work piece deformation will be reduced, tool life will be longer, production costs cost will be lower.

2), according to different processing job, speed can be selected.

3), with use of square alloy blades, four cutting edges can be used, replacement convenient, greatly reducing tool change time, both to ensure the accuracy

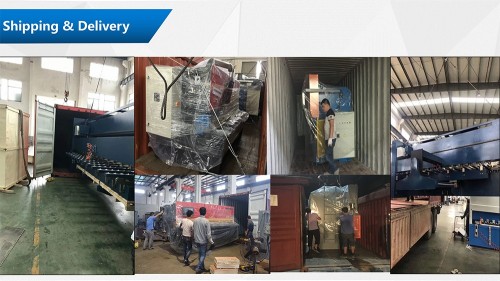

Our service

1. One year guarantee for components, and five years for the main machine.

2. We supply free training till u can catch it and can operate the machines adeptly.

3. U can call us or email us for any questions about the machine, we will reply u within 24hours.

4. During the warranty, if there is any problem about the componenets, we will send u the components wihin 24hous by DHL.

After-sales Service

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 1 year

4. Engineers available to service machinery oversea

.jpg)

.jpg)