|

Maanshan Durmapress Machinery Technology Co., LTD

|

metal cnc shearing machine

| Price: | 7600.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

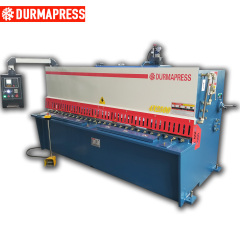

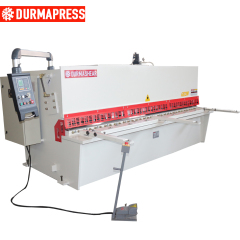

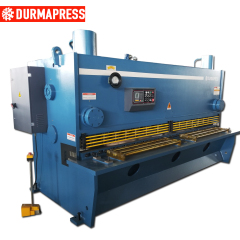

4mm metal sheet shearing machine

3200mm metal sheet cutting machine

swing beam shearing machine

QC12Y swing beam shearing machine

3m shearing

Product Description

cnc steel stainless plate sheet cut guillotine shearing machinery metal hydraulic shear metal shear machine qc11y/12y

| 1. Hydraulic individual sheet material clamping system with nylon inserts to protect material from indentation from the clamping cylinders along full length of machine. |

| 2. Simplified blade gap adjustments to allow for a wide range of material types |

| 3. Transfer balls inserted into work table allowing material to be easily moved to the cut position and squaring arm. |

| 4.Totally European design,streamlined looking,Frame: consists of right and left wall boards, working table, oil box, slot steel and etc. The stress of the welded parts can be eliminated by vibration. The machine enjoys high accuracy and high strength and can be transported easily. |

| 5.As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed. |

| 6.High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service. |

| 7.The machine by the European Union CE certification and ISO quality system certification |

| 8.Adopt integrated hydraulic control system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups and it is installed at the top of the oil box. |

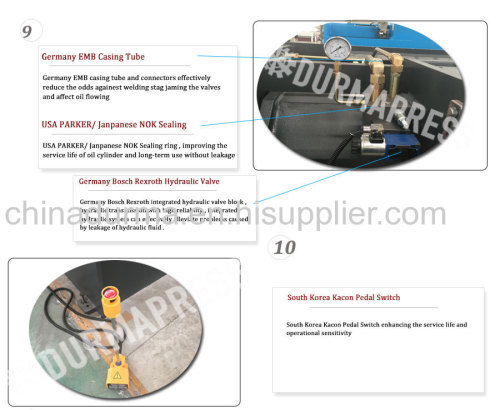

| 9.Every complete working cycle can be achieved through the control of hydraulic valve.The remote adjustment valve can adjust the working pressure at the right side of the wall board. |

| 10.All seals in cylinder is imported,the most famous brand,good quality and high performance |

| 11.Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly |

| 12.The cutting times of this machining tool is displayed on a Estun E10 NC and accurately show the cut after the block size and number display. |

| 13.The parallelism of the sheet to be cut off and the precision of the shear size can be ensured. The cut stroke and cut times also can be controlled. |

| 14.Light alignment device eases drawing line for cutting, Standard front support sheet frame, A set of standard blades |

| 15.System uses a bladder-type hydraulic accumulator as an auxiliary energy,absorb the pressure shock,the machine is running smooth,low noise. |

16.Adopt handwheel to rapidly and accurately adjust the blade clearance, Shearing in sections, shadow-line cutting. |

| 17.The rectangular monoblock blades featuring long life with 4 cutting edges, quality high-carbon high-chrome blades D2 quality. |

| 18. Shearing angle is Variable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal. |

| 19.System uses a bladder-type hydraulic accumulator as an auxiliary energy,absorb the pressure shock,the machine is running smooth,low noise. |

| 20.Optional:Holland Delem DAC350, DAC360, DAC310 or Estun E200 cnc controller automatically controls the backgauge, cutting stroke, cutting angle and the blades gap together the numbers of workpieces accurately. |

| 21.European key electrics and Hydraulic Valves Advanced integral hydraulic system with good reliablity-Imported from Germany. |

22.X axis back gauge clearance are controlled by E10s which ensures a higher cutting accuracy, Backgauge with Optional ball screw and line guide rail,, maximum stroke of backgauge can realize 1000mm. |

| No | Model | Max cut thickness mm | Max cut length mm | Ram Stroke n/min | Cutting angle ° | Motor kw | Machine Szie mm |

| 1 | 4x2500 | 4 | 2500 | 20-40 | 0.5-1.5 | 5.5 | 3100x1600x1700 |

| 2 | 4x3200 | 4 | 3200 | 20-40 | 0.5-1.5 | 7.5 | 3800x1800x1700 |

| 3 | 6x2500 | 6 | 2500 | 16-35 | 0.5-1.5 | 7.5 | 3150x1650x1700 |

| 4 | 6x3200 | 6 | 3200 | 14-35 | 0.5-1.5 | 7.5 | 3860x1810x1750 |

| 5 | 6x4000 | 6 | 4000 | 10-30 | 0.51.5 | 7.5 | 4630x2030x1940 |

| 6 | 6x5000 | 6 | 5000 | 10-30 | 0.5-1.5 | 11 | 5660x2050x1950 |

| 7 | 6x6000 | 6 | 6000 | 8-25 | 0.5-1.5 | 11 | 6680x2200x2500 |

| 8 | 8x2500 | 8 | 2500 | 14-30 | 0.5-1.5 | 11 | 3170x1700x1700 |

| 9 | 8x3200 | 8 | 3200 | 12-30 | 0.5-1.5 | 11 | 3870x1810x1780 |

| 10 | 8x4000 | 8 | 4000 | 10-25 | 0.5-1.5 | 11 | 4680x1900x1860 |

| 11 | 8x5000 | 8 | 5000 | 10-25 | 0.5-1.5 | 15 | 5680x2250x2200 |

| 12 | 8x6000 | 8 | 6000 | 8-20 | 0.5-1.5 | 15 | 6800x2350x2700 |

| 13 | 10x2500 | 10 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 14 | 10x3200 | 10 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 15 | 10x4000 | 10 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 16 | 10x5000 | 10 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 17 | 10x6000 | 10 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

| 18 | 12x2500 | 12 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 19 | 12x3200 | 12 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 20 | 12x4000 | 12 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 21 | 12x5000 | 12 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 22 | 12x6000 | 12 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

Why should I use a shearing machine?

The shearing machine is a kind of cutting equipment widely used in machining, which can shear the steel plate materials of various thicknesses. The shearing machine is a machine with a blade relative to another blade. It is borrowed from the upper blade of the movement and the fixed blade, which USES the reasonable blade clearance to apply a shear force to the metal sheet of various thicknesses so that the plates can break apart according to the required size.

| Item name | Shearing machine |

| Operation Panel | Pedal switch |

| Voltage | 380V, 3 Phase, 50HZ |

| weight | abour 3.2 ton |

| Certification | CE, ISO |

| Life Time | At Least 15 Years |

| Warranty | 12 Months |

| Suitable Material | PPGI, PI, CR, Q235 or equivalent |

Payment :

| Payment | There are 3 plans for you.you can choose the best plan. a.30% T/T deposit in advance and the balance of 70% is paid after confirmation and before shipping. b.Irrevocable LC at sight. c.30% TT deposit,and balance DA 60 days for part of countries with extra charges.Please contact me for details if you need this plan. |

| Delivery time | 1.With 45 working days after received deposit ,we will finish the machine. 2.We will take photos and videos for your confirmation. 3.You need send balance and make delivery within 1 month.After you send the balance,you can book container. 4.Once container is confirmed,we load the container within 5 days. |

Fit for ocean shipping.

The main body of machine fixed to the container by steel wire.

Spare parts in a box

.jpg)

.jpg)