|

Maanshan Durmapress Machinery Technology Co., LTD

|

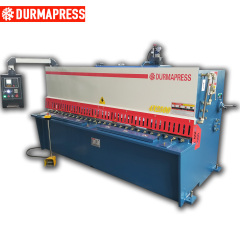

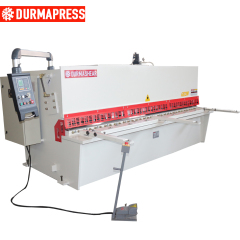

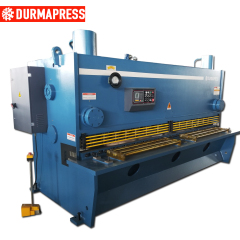

hydraulic shearing machine for sale

| Price: | 7600.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

6mm metal sheet shearing machine

2500mm metal sheet cutting machine

swing beam shearing machine

QC12Y swing beam shearing machine

2.5m shearing

QC12Y 6x2500 CE approved hydraulic shearing machine for sale, automatic cnc hydraulic guillotine shearing machine

Product Description

| QC12K 6x2500 CE approved hydraulic shearing machine for sale, automatic cnc hydraulic guillotine shearing machine Performance and Features |

| 1. The second generation of QC12K 6x2500 CE approved hydraulic shearing machine for sale, automatic cnc hydraulic guillotine shearing machine |

| 2. Rack, blade frame is entire welded, vibration to eliminate inner stress, to maintain good accuracy. |

| 3. Use advanced integrate hydraulic system and good reliability. |

| 4. Use three-point support rolling guide to eliminate the support gap, improve cut quality. |

| 5. The clearance between the blades adjusted by hand wheel rapidly, accurancy and convenient. |

| 6. Rectangular blade. four cutting edges, and loong service life. |

| 7. Adjustable shearing angle to reduce deformation of the sheet. |

| 8. The upper blade frame use introversion structure, easy for blanking to improve the accuracy of production. |

| 9. With the sub-shear function, motorized backgauge, digital display. |

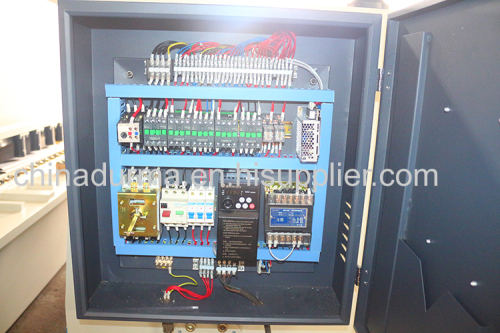

| Main Accessoies | Main Outsourcing Parts |

| CNC System | Dutch Delem310 |

| Hydraulic System | Germany Bosch/Hoerbiger |

| Servo System | China EDBO5 |

| Oil Sylinder | Jiangdu Yong Nut |

| Seals; Before the Carrier Aircraft | United States Parker; China |

| Main Electrical Components | Germany Siemens |

| Card of Joint Body | Germany EMB and United States Parker |

| Ball Screw; Linear Guider | Taiwan ABBA; Germony Lux LeDeXing |

| QC12K 6x2500 CE approved hydraulic shearing machine for sale, automatic cnc hydraulic guillotine shearing machine Optional Configuration | ||

| CNC System | DAC310 servo control system | 1. Bright LCD display. 275*48 pixels 2. Backgauge, blade clearance, shearing stroke control 3. Simutaneous display of the real position and the program 4. Value of backgauge 5. Shear counting 6. 100 procedures 7. Panel type installation 8. Servo control/variable frequency speed adjistment control/double-speed AC motor control |

| DAC360 servo control system | 1. Panel based housing 2. Bright LCD screen 3. Backgauge control 4. Retract function 5. Cutting angle control 6. Cutting gap control 7. Stroke length limitation 8. Force control 9. Manual movement of axes | |

| Feeding Device Feeding | CNC | |

| Care Feeding Device | Pneumatic care feeding | |

| Safety Device | Photoelectric protection, laser protection | |

| CNC System Installation | Rotatable suspension arm | |

| Model | 6*2500 | Unit |

| Cutting Thickness | 6 | mm |

| Cutting Length | 2500 | mm |

| Angle Range | 1-3 | o |

| Backgauge Stroke | 750 | mm |

| Approx. Weight | 6500 | KG |

| Dimension | 3040*1700*1700 | mm |

| Stroke Times | 6-20 | Times/min |

| Main Power | 11 | KW |

Packaging & Shipping

| Container is to be free of holes, vents closed, door seals in good condition to keep moisture out. |

| Container Bracing: Pipe Bending Machine is to be strapped with wire or webbing to ensure it evently within the container |

| If wood is sued, it must be heat treated and muat comply with U.S. regulations. |

| Container Packaging: Wrapped in pastic to protect from getting wet. |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Hydraulic Shearing Machine

Hydraulic Swing Shearing Machine

Shearing Machine

Hydraulic Guillotine Shearing

Hydraulic Shearing Machinery

CNC Shearing Machine

More>>

.jpg)

.jpg)