|

Maanshan Durmapress Machinery Technology Co., LTD

|

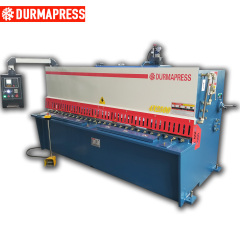

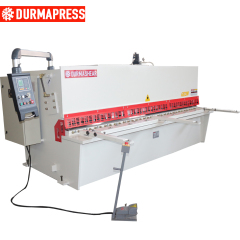

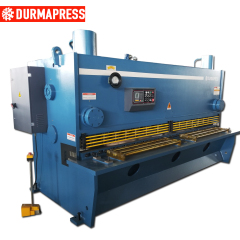

Mechanical Sheet Metal Shearing Machine

| Price: | 9900.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

Ma'anshan Durmapress Machinery Technology Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

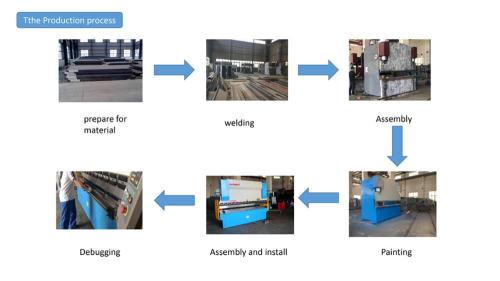

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

Specifications

cnc shearing machine tile cutting tools bending machine for metal cutting

1.CE&ISO

2.High precision

cnc shearing machine tile cutting tools bending machine for metal cutting

1.The mainframe is fitted with numeric-control system special for shearing machines.

2.The position of rear stopper is displayed in a real-time manner.

3.Multi-step programming function is available and the rear stopper is able for automatic operation and continuous positioning, to achieve an automatic adjustment for position of rear stopper.

4.It is provided with counting function for shearing machine, to display the shearing numbers in a real-time manner, able for power-failure memory of position of rear stopper, producedures, and parameters.

5.Imported ball bearing lead screw and linear guide rail are used , to ensure the positioning precision, so that the processing precision of machine is higher.

cnc shearing machine tile cutting tools bending machine for metal cutting

Main Features

●Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

●Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany

●Mechanical synchronous meahanism and the complex compensation are designed so as to raise the workpieces precision.

●The stroke and distance of the backgauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by E21.

●Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays.

●Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

Type | Cutting Thickness (mm) | Cutting Length (mm) | Cutting Angel (°) | Material Strength (KN/CM) | Stopper Adjust Range (mm) | Travel Times

| Power (kw) | Dimension L×W×H (mm) |

4×2500 | 4 | 2500 | 1°30′ | ≤450 | 20-500 | 16 | 5.5 | 3040×1550×1550 |

4×3200 | 4 | 3200 | 1°30′ | ≤450 | 20-500 | 13 | 5.5 | 3840×1550×1550 |

4×6000 | 4 | 6000 | 1°30′ | ≤450 | 20-800 | 5 | 7.5 | 6460×2100×3200 |

6×2500 | 6 | 2500 | 1°30′ | ≤450 | 20-500 | 15 | 7.5 | 3040×1710×1620 |

6×4000 | 6 | 4000 | 1°30′ | ≤450 | 20-600 | 9 | 7.5 | 4620×1850×1700 |

6×6000 | 6 | 6000 | 1°30′ | ≤450 | 20-800 | 5 | 11 | 6480×2100×2300 |

8×2500 | 8 | 2500 | 1°30′ | ≤450 | 20-500 | 11 | 11 | 3040×1700×1700 |

8×4000 | 8 | 4000 | 1°30′ | ≤450 | 20-600 | 8 | 11 | 4640×1700×1700 |

8×5000 | 8 | 5000 | 1°30′ | ≤450 | 20-600 | 8 | 11 | 5400×2400×2000 |

8×6000 | 8 | 6000 | 1°30′ | ≤450 | 20-800 | 8 | 15 | 6480×2100×2350 |

10×2500 | 10 | 2500 | 1°30′ | ≤450 | 20-500 | 10 | 15 | 3040×1800×1700 |

10×3200 | 10 | 3200 | 1°30′ | ≤450 | 20-500 | 10 | 15 | 3860×2000×1700 |

12×5000 | 12 | 5000 | 2° | ≤450 | 20-600 | 6 | 22 | 3245×1900×1900 |

16×6000 | 16 | 6000 | 2° | ≤450 | 20-800 | 5 | 22 | 6900×2600×2700 |

20×4000 | 20 | 4000 | 3° | ≤450 | 20-800 | 5 | 30 | 4850×2600×2400 |

Q1:How Can i calculate the Machine Capacity?

A: Max thickness x Max length x 1.25 x 6.5= Press Brake Capacity(Different Angle Different Die)

Q2:How about the machine warranty?Is the whole machine?

A:We can offer 4 years warranty for the following parts :

--Hydraulic System with pump and Valve

--Hydraulic Cylinders

--Electric units

--Hydraulic Cylinders

--Gasket Ring( We will send you extra with the machine also )

--Tube Connector

--Control Button

--Limit Switch

--Controller

During the warranty period we provide any accessories for free

Q3: How is your service after-sales?

A:We have 10 Engineers available to service machinery overseas

Q4: What is your delivery time?

A:We supply prompt delivery time:30-35 days.

Q5:What kind of payment does your company support?

A:T/T, L/C , Cash, Western Union are all accepted

.jpg)

.jpg)