|

Maanshan Durmapress Machinery Technology Co., LTD

|

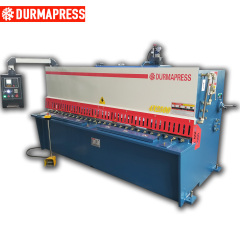

6*3200 CNC sheet metal cutting hydraulic shearing machine

| Price: | 9900.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

durmapress's is a comprehensive enterprise dealing economic and technology cooperation that specializes in manufacturing for metal fabrications and distributing of all types of machinery tools Including Industrial Equipment, fabricating equipment, sheet metal equipment and production line machinery.

We are not only trading with customers from domestic and oversea but also providing customers with technical, commutation and after sales support.

Our dedication to the highest quality products and services have establish excellent trade relations with customers from all over the world. EMM's team memebers includes qualified sales specialists and highly trained technical professional to help provide quick service and the best quality of work in order to meet our customer needs.

CE Certification for Shearing Machine and Press brake:

Notes of Both factories:

Jiang Su Hairui CNC Machine Tool Co,.Ltd and Anhui Haili Machine Tool Co., Ltd belongs to the same boss. Both company are focusing on press brake, shearing machine, notching machine and v groover machine , rolling machine and so on! When Hairui factory is newly built up for manufacturing higher standard CNC machines, please understand! We had passed CE, ISO, BV certifications in the past years.

QC12Y/K Hydraulic Swing Beam Shearing Machine

1.The frame is entirely welded with steel plates,and treated to relive stress by tempering.

2.Hydraulic drive ,return of knife beam is smooth and prompt by accumulator or nitrogen cylinder.

3.The portable and prompt adjustment of the blades gap and the value of gap are indicated by didital, convenient and fast.

4.Equipped with lighting-alignment,so as to align when shearing,The stroke of klnife beam can be adjusted in stepless mode.

5.Protection fence to ensure the opration safety.

6.The display devices of the backgauge value and the shearing times are on the front of the machine.

1. Assisting blade pedestal on worktable is convenient for micro adjustment.

2. Rolling material support ball is provided on worktable, convenient operation.

3. Using stepless adjusting structure to regulate the gap of blades, adapt to different thickness and materials.

4. The adoption of four-side edge shearing blade prolongs the service life of blade.

5. Regulating shearing process not only increases the production efficiency but also achieve the function of segmentshearing.

6. It is provided with counting function for shearing to decrease the numerous artifical counting.

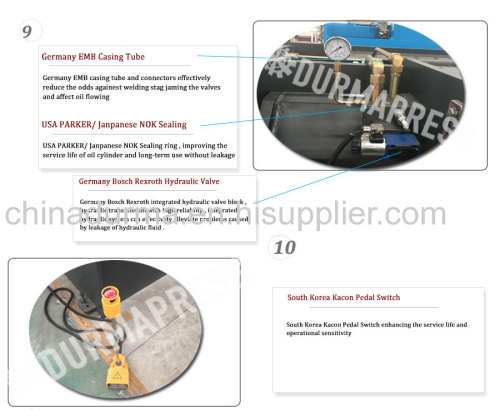

Main components deployment list

| Hydraulic system: | Omega |

| Sealing pieces: | Japanese NOK |

| Oil pump: | Shanghai Chengjie |

| Electrical pieces: | Schneider |

| NC Controller | Estun E21S |

| Shear Blade: | Shanghai JINSHAN |

| Ball Screw(Option): | TAIWAN HIWIN |

| Linear Guide way(Option) | TAIWAN HIWIN |

X-Axis Backague Control E21S (Standard):

- Positioning Control of Backague

- Intelligent positioning control

- One side and two-side positioning which eliminated spindle clearance effectively

-Retract function

- Automatic reference searching

- One-key parameter backup and restore

- Fast position indexing

- 40 programs storage space, each program has 25 steps

- Power off protection

Model | Cutting Thickness | Cutting Length | Cutting Angle | Travel Time | Backgauge Stroke | Motor | Dimension (L x W x H) |

mm(450N/m2) | mm | ° | Min-1 | mm | kw | Mm | |

4 x 2500 | 4 | 2500 | 1°30′ | 16 | 20~500 | 5.5 | 3040 x 1550 x 1550 |

4 x 3200 | 4 | 3200 | 1°30′ | 13 | 20~500 | 5.5 | 3840 x 1550 x 1550 |

4 x 4000 | 4 | 4000 | 1°30′ | 10 | 20~600 | 5.5 | 4600 x 1700 x 1700 |

4 x 6000 | 4 | 6000 | 1°30′ | 5 | 20~800 | 7.5 | 6460 x 2100 x 2300 |

6 x 2500 | 6 | 2500 | 1°30′ | 15 | 20~500 | 7.5 | 3040 x 1710 x 1620 |

6 x 3200 | 6 | 3200 | 1°30′ | 12 | 20~500 | 7.5 | 3840 x 1710 x 1620 |

6 x 4000 | 6 | 4000 | 1°30′ | 9 | 20~600 | 7.5 | 4620 x 1850 x 1700 |

6 x 5000 | 6 | 5000 | 1°30′ | 8 | 20~600 | 7.5 | 5640 x 1900 x 2000 |

6 x 6000 | 6 | 6000 | 1°30′ | 5 | 20~800 | 18.5 | 6480 x 2100 x 2300 |

8 x 2500 | 8 | 2500 | 1°30′ | 11 | 20~500 | 7.5 | 3040 x 1700 x 1700 |

8 x 3200 | 8 | 3200 | 1°30′ | 8 | 20~500 | 7.5 | 3860 x 1700 x 1700 |

8 x 4000 | 8 | 4000 | 1°30′ | 8 | 20~600 | 7.5 | 4640 x 1700 x 1700 |

8 x 5000 | 8 | 5000 | 1°30′ | 8 | 20~500 | 7.5 | 5400 x 2400 x 200 |

8 x 6000 | 8 | 6000 | 1°30′ | 8 | 20~800 | 18.5 | 6480 x 2100 x 2350 |

10 x 2500 | 10 | 2500 | 1°30′ | 8 | 20~500 | 7.5 | 3040 x 1800 x 1700 |

10 x 3200 | 10 | 3200 | 2° | 10 | 20~500 | 11 | 3860 x 2000 x 1700 |

10 x 4000 | 10 | 4000 | 2° | 10 | 20~600 | 11 | 4650 x 2100 x 2000 |

10 x 6000 | 10 | 6000 | 1°30′ | 10 | 20~800 | 18.5 | 6500 x 2100 x 2300 |

12 x 2500 | 12 | 2500 | 1°40′ | 12 | 20~600 | 18.5 | 3140 x 2050 x 2000 |

12 x 3200 | 12 | 3200 | 1°40′ | 10 | 20~600 | 18.5 | 3880 x 2150 x 2000 |

12 x 4000 | 12 | 4000 | 1°40′ | 10 | 20~600 | 18.5 | 4680 x 2150 x 2000 |

12 x 5000 | 12 | 5000 | 2° | 6 | 20~600 | 18.5 | 5800 x 2400 x 2400 |

12 x 6000 | 12 | 6000 | 2° | 5 | 20~800 | 22 | 6900 x 2600 x 2700 |

16 x 2500 | 16 | 2500 | 2°30′ | 10 | 20~100 | 18.5 | 3140 x 2150 x 2100 |

16 x 3200 | 16 | 3200 | 2°30′ | 10 | 20~600 | 18.5 | 3880 x 2150 x 200 |

16 x 4000 | 16 | 4000 | 2°30′ | 10 | 20~800 | 37 | 4650 x 21580 x 2200 |

16 x 5000 | 16 | 5000 | 2° | 6 | 20~100 | 18.5 | 5900 x 2600 x 2700 |

16 x 6000 | 16 | 6000 | 2° | 5 | 20~1000 | 22 | 6900 x 2700 x 2700 |

20 x 2500 | 20 | 2500 | 2°30′ | 8 | 20~800 | 22 | 3440 x 2300 x 2500 |

20 x 3200 | 20 | 3200 | 2°30′ | 8 | 20~1000 | 22 | 4150 x 2350 x 2700 |

20 x 4000 | 20 | 4000 | 2°30′ | 5 | 20~1000 | 22 | 4850 x 2600 x 2400 |

20 x 6000 | 20 | 6000 | 2°30′ | 4 | 20~1000 | 37 | 6700 x 3000 x 3000 |

25 x 2500 | 25 | 2500 | 3° | 8 | 20~1000 | 37 | 3200 x 2700 x 2900 |

25 x 3200 | 25 | 3200 | 3° | 5 | 20~1000 | 37 | 4200 x 2400 x 2500 |

30 x 2500 | 30 | 2500 | 3° | 4 | 20~1000 | 40 | 3300 x 2900 x 3000 |

30 x 3200 | 30 | 3200 | 3°30′ | 4 | 20~1000 | 40 | 4200 x 2500 x 2600 |

40 x 2500 | 40 | 2500 | 4° | 3 | 20~1000 | 75 | 3200 x 3300 x 3200 |

40 x 3200 | 40 | 3200 | 4° | 3 | 20~1000 | 90 | 4300 x 3300 x 3000 |

Required specifications

NO | Item | Parameter value | Unit |

1 | Cutting thickness | 6 | MM |

2 | Cutting length | 3200 | MM |

3 | Travel times | 14-28 | t/min |

4 | Distance of back gauge | 20-750 | MM |

5 | Cutting angle | 0.5-1.5 | |

6 | Motor power | 7.5 | KW |

7 | Dimension(L*W*H) | 4400x1800x1800 | MM |

8 | Control | NC89 | |

9 | Weight | Nearly 9 | ton |

10 | Back guage motor | Model AO2-8026 Power 3.5KW Rotate speed: 900R/min | |

11 | Gear pump | Model :NB2-G63F Rate of flow :63L/min Pressure 31.5Mpa |

Our service :

We assist customers in well understanding the product information like features, functions and applications and so on. As for the detailed procuring information or drawings, our professionals will first conduct a careful examination and then recommend the most suitable machines or devise proper schemes for customers. We also provide free samples if necessary.

Service during the Sale

1. We are manned with professional salesmen and technicians to provide the information, technical support and the optimal solutions with high cost performance.

2. Based on the specific requirements of customers and the lead time, we will formulate a rigorous operation process. Through the close cooperation of Commodity Department, Sales Department, Technical Department and the Ocean Shipping Department, we are devoted to timely supplying customers with superior machines.

3. Generally, certain quantity of quick-wear parts will be delivered with the goods. The delivery deadline depends on the specific order, which is usually within 1 to 3 months.

After-Sale Service

1. One year warranty is provided.

2. Customers can send photos or samples for our confirmation once the parts are damaged within the one year warranty. If the parts are not damaged by misoperation , we will reply to customers within 48 hours and provide free parts for replacement. Besides, for the parts out of commission and beyond the

warranty, we only charge for the basic costs of parts.

3. We regularly follow up the service condition of products, and timely analyze and copy with the feedbacks. As for the disputes, we will figure out effective actions to reach mutual satisfaction.

Company Information

.jpg)

.jpg)