|

Maanshan Durmapress Machinery Technology Co., LTD

|

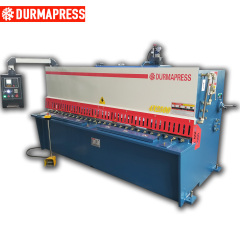

sheet metal plate 6mm cutting machine

| Qty (Set/Sets) | Unit Price (9700.0~9800.0 USD) |

| 1 | 9800 |

| 2 + | 9700 |

| Trade Term: | FOB,CFR,CIF,DAT,DDP,DAP,CIP,CPT,EXW |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model Number:

AC/MS7-6x3200

Voltage:

220V/380V

Rated Power:

7.5kw

Dimension(L*W*H):

4090*1600*1690mm

Weight:

6500kg

Certification:

CE ISO

ONE. TECHNOLOGY DATA OF hydraulic sheet metal plate 6mm cutting machine

* | Specification | Value | Unit |

1 | Shearing thickness (Q235A) | 6 | mm |

2 | Shearing width | 4000 | mm |

3 | plate tensile strength | 450 | n/mm2 |

4 | Shearing angler | 0.5-2.5 | degree |

5 | Strokes | 8-20 | n/min |

6 | Throat depth | 200 or more | mm |

7 | Length of blade | 1300*3+1500 | mm |

8 | Blade material | 6CrW2Si | CrW2Si |

9 | Height of working table | 800 | mm |

10 | Bckgauge range | 20-600 | mm |

11 | Main motor power | 7.5 | kw |

12 | Oil pump | 40 | L/min |

13 | Measurement | 4700*1800*2100mm | mm |

14 | Weight | 7500 | kg |

15 | Votage | 380V/50Hz/3Phase | v |

16 | Number of hold downs | 26 | piece |

TWO. FEATURE of hydraulic sheet metal plate 6mm cutting machine

1.It's very popular in metalworking market for cutting metal sheets

2.Various model of cutting 4-40mm thickness and 1000-9000mm length.

3.Steel welded construction, vibrating aging function

4.Shearing gap can be adjusted stepless at will and can do sectional cut

6.Motorized back gauge and cutting number can digital readout ,E10 or CNC100

7.Power break protection device to guarantee safety during maintenance

8. Debug and goodafter-sales service

THREE. EQUIPMENTS CAN INSTALLED ACCORDING TO CUSTOMER

Digital readout: E21 or others

Hydraulic system: Bosch or others

Pump: Gear pump

Electrics: Germany simens or schnider

Seal: DZ or NOK or VALQUA

Straight-line guide: HIWIN or ABBA

Lighting alignment: Famous brand

Foot pedal: Karcon

Punch and Die: Shanghai eryeC

CNC ZR41,DAC310,DAC360

Parts of our machine below:

Finger safety protection

All the pipes and Tubing connector are from Germany EMB

No clearance design in ball bearing plate

Back safe protection :

Main Features: |

| 1.Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment. |

| 2.Accurl engineers utilize parametric 3D SolidWorks using FEM & DOE analysis as well as static and mechanism analysis. |

| 3.Accurl Hydraulic Shearing Machine is a Swing Beam Action machine which is produced in a variety of cutting lengths and capacity options. |

| 3. Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany, |

| 4. Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode. |

5. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder. |

| 6. CE conformity including Tiltable Fornt Finger Guard and Optical Rear Safety Guard, |

7. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety. |

|

| Standard Equipment: |

| 1. Rapid and precise blade clearance adjustment by single handle on the side frame |

| 2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel |

| 3. Cutting Line Illumination and wire for shadow line cutting |

| 4. Counter of Strokes, Cutting Length Adjustment |

5. Hydraulic and Electrical overload protection |

6. Squaring Arm and Front Support Arms |

7. Estun E21s NC control |

| 8. Germany Bosch-Rexroth Hydraulic |

| 9. Telemecanique/SchneiderElectrics |

| 10. Hydraulic and Electrical overload protection |

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy. |

12. Side guard is standard meeting CE regulations. |

|

Better Cuttings: |

1.Backgauge adjustment according to blade gap. |

2.Backgauge retraction feature. |

3.Sub-program and programming loop. |

4.Sequence repeat function. |

5.Auto cutting (Flying cut). |

|

| Estun E21s NC Shearing Machine Control system: |

| 1. Monochrome LCD Box Panel. |

| 2. Integral factor programmable freely |

| 3. Automatic positioning control |

| 4.Spindle allowance offset |

| 5.Internal time relay |

| 6.Stock counter |

7.Backgauge position display, resolution in 0.05mm |

The best cutting results You can cutt longer and narrow parts with standard AC/MS7-Cutt Series. |

Our Services

1.Standardization of Service "212" |

| 2: response in 2 hours |

| 1: provide solution in 1 day |

| 2: solve complaint in 2 days |

| 2.Installation Service |

| Installation Services are available with all Accurl machines. We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel ) |

| 3.Training Service |

| Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. |

| 4.Quality Guarantee |

| We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. |

| We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments. |

| Machine warranty is 3 year. We offer flexible extended warranties if needed. |

.jpg)

.jpg)