|

Maanshan Durmapress Machinery Technology Co., LTD

|

16*3200 automatic metal sheet plate shearing machine

| Price: | 14900.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

durmapress is a comprehensive enterprise dealing economic and technology cooperation that specializes in manufacturing for metal fabrications and distributing of all types of machinery tools Including Industrial Equipment, fabricating equipment, sheet metal equipment and production line machinery.

We are not only trading with customers from domestic and oversea but also providing customers with technical, commutation and after sales support.

Our dedication to the highest quality products and services have establish excellent trade relations with customers from all over the world. EMM's team memebers includes qualified sales specialists and highly trained technical professional to help provide quick service and the best quality of work in order to meet our customer needs.

Machine Features

1.This machine adopts the steel plate welded structure, the fuselage uses the finite element analysis and design, vibration stress relief, the fuselage is stable and reliable.

2.By using the three point support rolling wheel, the elimination of supporting gap, improving shearing accuracy.

3.Carriage of shearing angle can be adjusted

4.Shearing stroke adjusted, improved work efficiency, can realize sectional shear.

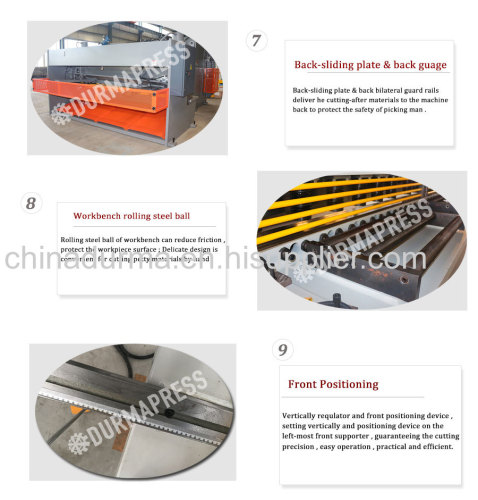

5.After the block design manual lifting function, easy long plate shearing.

6.The inner side of the wall is provided with a manual oil pump ,convenient operation, ensure the lubrication.

7.Cartridge type hydraulic system oil temperature, slow ascending, enhance there liability and safety of the machine tool operation.

Technical parameters

| Type | Unit | QC11Y-16×3200 |

| Max. cutting thickness | mm | 16 |

| Max. cutting width | mm | 3200 |

| Can be cut strength of plate | Mpa | 450 |

| Shearing angle | ° | 0.5~3.5° |

| Stroke time | times/min | 12~20 |

| Backgauge range | mm | 20-800 |

| Motor power | kw | 22 |

| Machine size | mm | 3950x1950x2650 |

Characterastics

1. Assisting blade pedestal on worktable is convenient for micro adjustment.

2. Rolling material support ball is provided on worktable, convenient operation.

3. Using stepless adjusting structure to regulate the gap of blades, adapt to different thickness and materials.

4. The adoption of four-side edge shearing blade prolongs the service life of blade.

5. Regulating shearing process not only increases the production efficiency but also achieve the function of segmentshearing.

6. It is provided with counting function for shearing to decrease the numerous artifical counting.

Main components deployment list

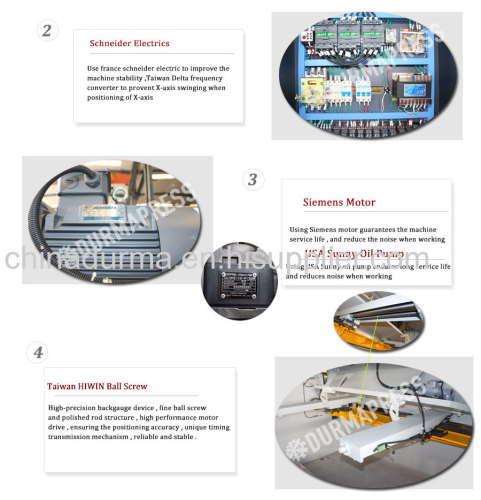

| Hydraulic system: | Omega |

| Sealing pieces: | Japanese NOK |

| Oil pump: | Shanghai Chengjie |

| Electrical pieces: | Schneider |

| NC Controller | Estun E21S |

| Shear Blade: | Shanghai JINSHAN |

| Ball Screw(Option): | TAIWAN HIWIN |

| Linear Guide way(Option) | TAIWAN HIWIN |

X-Axis Backague Control E21S (Standard):

- Positioning Control of Backague

- Intelligent positioning control

- One side and two-side positioning which eliminated spindle clearance effectively

-Retract function

- Automatic reference searching

- One-key parameter backup and restore

- Fast position indexing

- 40 programs storage space, each program has 25 steps

- Power off protection

Model | Cutting Thickness | Cutting Length | Cutting Angle | Travel Time | Backgauge Stroke | Motor | Dimension (L x W x H) |

mm(450N/m2) | mm | ° | Min-1 | mm | kw | Mm | |

4 x 2500 | 4 | 2500 | 1°30′ | 16 | 20~500 | 5.5 | 3040 x 1550 x 1550 |

4 x 3200 | 4 | 3200 | 1°30′ | 13 | 20~500 | 5.5 | 3840 x 1550 x 1550 |

4 x 4000 | 4 | 4000 | 1°30′ | 10 | 20~600 | 5.5 | 4600 x 1700 x 1700 |

4 x 6000 | 4 | 6000 | 1°30′ | 5 | 20~800 | 7.5 | 6460 x 2100 x 2300 |

6 x 2500 | 6 | 2500 | 1°30′ | 15 | 20~500 | 7.5 | 3040 x 1710 x 1620 |

6 x 3200 | 6 | 3200 | 1°30′ | 12 | 20~500 | 7.5 | 3840 x 1710 x 1620 |

6 x 4000 | 6 | 4000 | 1°30′ | 9 | 20~600 | 7.5 | 4620 x 1850 x 1700 |

6 x 5000 | 6 | 5000 | 1°30′ | 8 | 20~600 | 7.5 | 5640 x 1900 x 2000 |

6 x 6000 | 6 | 6000 | 1°30′ | 5 | 20~800 | 18.5 | 6480 x 2100 x 2300 |

8 x 2500 | 8 | 2500 | 1°30′ | 11 | 20~500 | 7.5 | 3040 x 1700 x 1700 |

8 x 3200 | 8 | 3200 | 1°30′ | 8 | 20~500 | 7.5 | 3860 x 1700 x 1700 |

8 x 4000 | 8 | 4000 | 1°30′ | 8 | 20~600 | 7.5 | 4640 x 1700 x 1700 |

8 x 5000 | 8 | 5000 | 1°30′ | 8 | 20~500 | 7.5 | 5400 x 2400 x 200 |

8 x 6000 | 8 | 6000 | 1°30′ | 8 | 20~800 | 18.5 | 6480 x 2100 x 2350 |

10 x 2500 | 10 | 2500 | 1°30′ | 8 | 20~500 | 7.5 | 3040 x 1800 x 1700 |

10 x 3200 | 10 | 3200 | 2° | 10 | 20~500 | 11 | 3860 x 2000 x 1700 |

10 x 4000 | 10 | 4000 | 2° | 10 | 20~600 | 11 | 4650 x 2100 x 2000 |

10 x 6000 | 10 | 6000 | 1°30′ | 10 | 20~800 | 18.5 | 6500 x 2100 x 2300 |

12 x 2500 | 12 | 2500 | 1°40′ | 12 | 20~600 | 18.5 | 3140 x 2050 x 2000 |

12 x 3200 | 12 | 3200 | 1°40′ | 10 | 20~600 | 18.5 | 3880 x 2150 x 2000 |

12 x 4000 | 12 | 4000 | 1°40′ | 10 | 20~600 | 18.5 | 4680 x 2150 x 2000 |

12 x 5000 | 12 | 5000 | 2° | 6 | 20~600 | 18.5 | 5800 x 2400 x 2400 |

12 x 6000 | 12 | 6000 | 2° | 5 | 20~800 | 22 | 6900 x 2600 x 2700 |

16 x 2500 | 16 | 2500 | 2°30′ | 10 | 20~100 | 18.5 | 3140 x 2150 x 2100 |

16 x 3200 | 16 | 3200 | 2°30′ | 10 | 20~600 | 18.5 | 3880 x 2150 x 200 |

16 x 4000 | 16 | 4000 | 2°30′ | 10 | 20~800 | 37 | 4650 x 21580 x 2200 |

16 x 5000 | 16 | 5000 | 2° | 6 | 20~100 | 18.5 | 5900 x 2600 x 2700 |

16 x 6000 | 16 | 6000 | 2° | 5 | 20~1000 | 22 | 6900 x 2700 x 2700 |

20 x 2500 | 20 | 2500 | 2°30′ | 8 | 20~800 | 22 | 3440 x 2300 x 2500 |

20 x 3200 | 20 | 3200 | 2°30′ | 8 | 20~1000 | 22 | 4150 x 2350 x 2700 |

20 x 4000 | 20 | 4000 | 2°30′ | 5 | 20~1000 | 22 | 4850 x 2600 x 2400 |

20 x 6000 | 20 | 6000 | 2°30′ | 4 | 20~1000 | 37 | 6700 x 3000 x 3000 |

25 x 2500 | 25 | 2500 | 3° | 8 | 20~1000 | 37 | 3200 x 2700 x 2900 |

25 x 3200 | 25 | 3200 | 3° | 5 | 20~1000 | 37 | 4200 x 2400 x 2500 |

30 x 2500 | 30 | 2500 | 3° | 4 | 20~1000 | 40 | 3300 x 2900 x 3000 |

30 x 3200 | 30 | 3200 | 3°30′ | 4 | 20~1000 | 40 | 4200 x 2500 x 2600 |

40 x 2500 | 40 | 2500 | 4° | 3 | 20~1000 | 75 | 3200 x 3300 x 3200 |

40 x 3200 | 40 | 3200 | 4° | 3 | 20~1000 | 90 | 4300 x 3300 x 3000 |

1. Payment Terms

T/T, L/C at sight is acceptable by us.

2. Price Terms

It is up to your requirement. EX-WORS, FOB, CIF, CFR and so on are acceptable by us.

3. Delivery Time

15 Days from our accountant confirm your deposit payment.

4. Shipment Condition

We will arrange the machine production from our accountant confirm your deposit payment. The deposit is 30% of the contract.

The balance should be paid up before loading machines.

5. Warranty

1 year quality guaranty for the main spare parts, not include quick-wears parts, like blade, punch, die and so on. If the parts of machines have problems, which are caused by its own quality, we will provide the accessories for free.

.jpg)

.jpg)