|

Maanshan Durmapress Machinery Technology Co., LTD

|

China 6*3200 plate hydraulic shearing machine with certificate

| Price: | 9900.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance

Ma'anshan Durmapress Machinery Technology Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

Mechanical Shearing machine Features:

Manually adjusting the upper and lower blade gap according to different material and thickness, good shearing quality.

Four-sideedge blade with long service life.

Electromagnetic driving style to fast speed and lower noise.

1.Fabricated steel structure, with compact, construction, light weight and good rigidity stability

2. Integrated hydraulic transmission system, with good reliability

3.Back gauge use intelligent digital display device, shear quantity can be automatic counted, distance of back gauge can be set according to requirements of customers

4. The moving orbit of the blade beams inclines forwards to the supporting surface of the bottom blade, so you can gain fine shear surface. Jacking screws of the top blade provide a fine adjustment to minimize "rag" or "burring" on the sheared edge of the material

The hold-down assembly adopts the butterfly springs. There are antiskid heel block on the hold-down device of hold-down plate. The pressure is bigger, but it doesn't damage the sheet-metal surface.

5. The machine is drived by a self-contained, totally enclosed gearbox mounted directly on the main shaft. Its construction is compact and the gear is well lubricated with low noise and long life.

6. The machine hasn't the clutch and the flywheel. It shears the sheet-metal directly drived by the magnetic brake motor. This reduces the idle time of the motor and saves the energy.

7. The front and back gauges are provided with the scale plate displaying the scale. The back gauge may be easily adjusted in synchronism.

Mechanical Shearing machine Character:

1.Fabricated steel structure, with compact,construction,light weight and good rigidity stability

2. Integrated hydraulic transmission system, with good reliability

3.Back gauge use intelligent digital display device, shear quantity can be automatic counted, distance of back gauge can be set according to requirements of customers

4. The moving orbit of the blade beams inclines forwards to the supporting surface of the bottom blade, so you can gain fine shear surface. Jacking screws of the top blade provide a fine adjustment to minimize "rag" or "burring" on the sheared edge of the material

The hold-down assembly adopts the butterfly springs. There are antiskid heel block on the hold-down device of hold-down plate. The pressure is bigger, but it doesn't damage the sheet-metal surface.

5. The machine is drived by a self-contained, totally enclosed gearbox mounted directly on the main shaft. Its construction is compact and the gear is well lubricated with low noise and long life.

6. The machine hasn't the clutch and the flywheel. It shears the sheet-metal directly drived by the magnetic brake motor. This reduces the idle time of the motor and saves the energy.

7. The front and back gauges are provided with the scale plate displaying the scale. The back gauge may be easily adjusted in synchronism.

The whole structure of machine and Characteristics

- Totally European design, streamlined looking, Frame: consists of right and left wall boards, working table, oil tank, slot steel and etc. The stress of the welded parts can be eliminated by vibration. The machine enjoys high accuracy and high strength and can be transported easily.

-As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

- High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

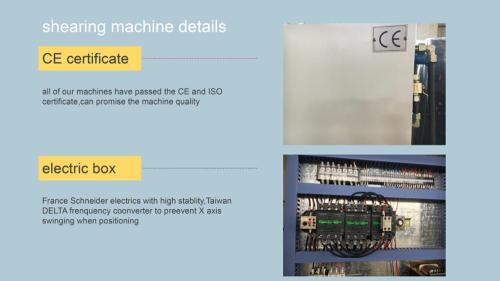

- The machine by the European Union CE certification and ISO quality system certification

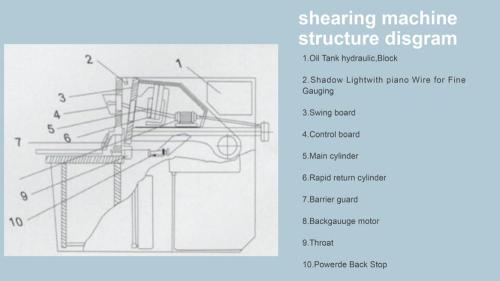

Hydraulic system

- Adopt integrated hydraulic control system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups and it is installed at the top of the oil tank

- Every complete working cycle can be achieved through the control of hydraulic valve.

-Extremely reliable and precise valves are used for the regulating circuit

-Overload overflow protection is outfitted to hydraulic system, which can assure no leakage, and the oil level can be read or seen directly

Cutting control system

- The cutting times of this machining tool is displayed on a A60 NC and accurately show the cut after the back gauge size and number display.

- The parallelism of the sheet to be cut off and the precision of the shear size can be ensured. The cut stroke and cut times also can be controlled.

- Light alignment device eases drawing line for cutting, standard front support sheet frame, a set of standard blades

- System uses a bladder-type hydraulic accumulator as an auxiliary energy, absorb the pressure shock, the machine is running smooth, low noise.

Blade adjust and cutting precision

- Adopt handwheel to rapidly and accurately adjust the blade clearance, Shearing in sections, shadow-line cutting.

- The rectangular monoblock blades featuring long life with 4 cutting edges, quality high-carbon high-chrome blades D2 quality.

- Shearing angle is variable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal.

Advance technology and procedures

- Optional: Holland Delem DAC350, DAC360, DAC310 or Estun E200 cnc controller automatically controls the backgauge, cutting stroke, cutting angle and the blades clearance together the numbers of workpieces accurately.

- European key electrics and Hydraulic valves advanced integral hydraulic system with good reliability-imported from Germany.

-X axis back gauge clearance are controlled by E20 which ensures a higher cutting accuracy, Backgauge with Optional ball screw and line guide rail,, maximum stroke of backgauge can realize 800mm.

Electrical system and the safety device

- Electrical components are imported or from Sino-foreign joint venture, in accordance with international standards, reliable safety, long life, good anti-interference ability, a radiation unit is fitted in electrical cabinet.

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch, easy to operate.

- Emergency stops on machine and foot switch for safety and Fence like body guard is standard or light curtain is optional

1.Standardization of Service "212" |

| 2: Response in 2 hours |

| 1: Provide solution in 1 day |

| 2: Solve complaint in 2 days |

| 2.Installation Service |

| Installation Services are available with all Pacific machines.We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel ) |

| 3.Training Service |

| Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. |

| 4.Quality Guarantee |

| We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. |

| We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments. |

| Machine warranty is 1 year. We offer flexible extended warranties if needed. |

Q1:How Can i calculate the Machine Capacity?

A: Max thickness x Max length x 1.25 x 6.5= Press Brake Capacity(Different Angle Different Die)

Q2:How about the machine warranty?Is the whole machine?

A:We can offer 4 years warranty for the following parts :

--Hydraulic System with pump and Valve

--Hydraulic Cylinders

--Electric units

--Hydraulic Cylinders

--Gasket Ring( We will send you extra with the machine also )

--Tube Connector

--Control Button

--Limit Switch

--Controller

During the warranty period we provide any accessories for free

Q3: How is your service after-sales?

A:We have 10 Engineers available to service machinery overseas

Q4: What is your delivery time?

A:We supply prompt delivery time:30-35 days.

Q5:What kind of payment does your company support?

A:T/T, L/C , Cash, Western Union are all accepted

.jpg)

.jpg)