|

Maanshan Durmapress Machinery Technology Co., LTD

|

WC67K 1252500 nc press brake

| Price: | 14300.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Anhui, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

China Well-Known Trademark

Machine Top 500 China

Anhui Top Brand

Durmapress WE67Y 100/2500 Press Brake

Model: DMPE-10025 ( WE67K-100/2500 )

Durmapress Founded in 2006,Maanshan Durmapress CNC Machinery Co.,Ltd is located in the Maanshan city ,Dangtu County,close to Nanjing Airport. Our geographical position is superior and the transportation is very convenient. Our company covers an area of 160 acres with the registered capital of 32,000,000 Yuan. We have more than 320 employees, including all types of engineering and technical personnel, serving the company R&D, production, and customers' service. At the same time, we have our own sales companies in each major and medium city.

Our main products are:CNC Press Brake,Guillotine Shearing Machine,Ironworker,power press ,and rolling machine these sheet metal processing equipmments.we are using advanced technology from German,Japan,and Italy,France and so on.

China Well-Known Trademark

Machine Top 500 China

Anhui Top Brand

Durmapress WE67Y 160/2500 Press Brake

Model: DMPE-10025 ( WE67K-160/2500 )

Control system: E21 NC control system

Features

Advanced proportional valve controls the hydraulic cyliners to work synchronously and achieve precise repeatability performance. Be capable of being controlled at random point within the stroke. Repeatability precision +/-0.01mm, parallelism precision +/-0.02mm. Deflection compensation table or crowing system for high precision. Ram stroke (Y1, Y2) and back gauge(X,R,Z) are controlled by CNC. Back gauge installed with ball screw and linear guide rail, ensuring high accuracy of repetition. Muilti-axis CNC controlled synchronous press brake available as metal fabricating center.

WC67Y Hydraulic Press Brake Specifications

Items | unit | 63/2500 | 63/3200 | 100/2500 | 100/3200 | 100/4000 | 125/2500 | 125/3200 | 125/4000 |

Nominal pressure | kN | 630 | 630 | 1000 | 1000 | 1000 | 1250 | 1250 | 1250 |

Length of table | mm | 2500 | 3200 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 |

Distance between uprights | mm | 2050 | 2600 | 2050 | 2600 | 3300 | 2050 | 2600 | 3200 |

Throat depth | mm | 250 | 250 | 320 | 320 | 320 | 320 | 320 | 320 |

Ram stroke | mm | 100 | 100 | 150 | 150 | 150 | 150 | 150 | 150 |

Max. open height between ram and table | mm | 345 | 345 | 415 | 415 | 415 | 415 | 415 | 415 |

Adjustment of Ram stroke | mm | 75 | 75 | 120 | 120 | 120 | 120 | 120 | 120 |

Approach speed | mm/s | 90 | 90 | 120 | 120 | 120 | 110 | 110 | 110 |

Bend speed | mm/s | 8 | 8 | 13 | 13 | 13 | 10 | 10 | 10 |

Return speed | mm/s | 66 | 66 | 115 | 115 | 115 | 100 | 100 | 100 |

Main motor | kW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 |

Overall dimension ( LxWxH ) | mm | 2560 | 3260 | 2650 | 3350 | 4150 | 2650 | 3350 | 4150 |

1725 | 1725 | 1785 | 1785 | 1785 | 1785 | 1785 | 1785 | ||

2280 | 2280 | 2460 | 2510 | 2560 | 2540 | 2560 | 2610 | ||

Weight | kg | 4400 | 5200 | 6100 | 7000 | 79000 | 6600 | 7300 | 8800 |

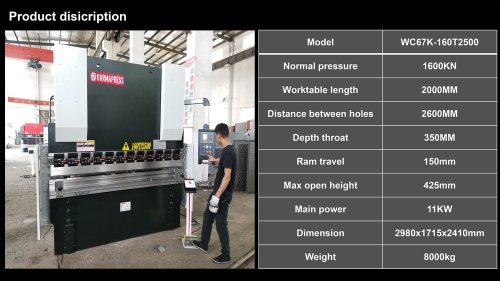

The discription of WC67Y-160T/2500

Product: TP10 NC Press Brake Control system hydraulic plate bending machine with Powered Depth Axis

Main Features:

1. Totally European design, streamlined looking,Monoblock,Welded steel frame rigid to deflection moment and high tensile with ST44 A1 material.

2. HS PRESS BRAKE is Equipped with the Estun user-friendly user interface,the TP10 provides all main press brake functionality.

3. Automatic tonnage and stroke adjustment for bending angles.Perfect bending results with easy angle input and operation of machine.

4. All tubes are connected by tube insertings to avoid oil lost and burst by welding tubes.

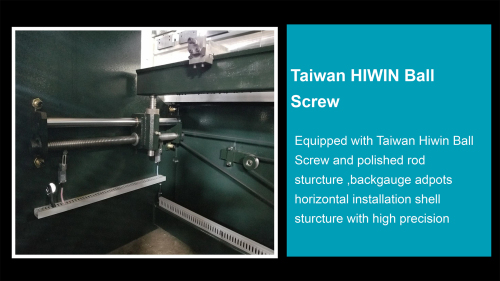

5. Ball screw and line guide was designed to improve precision.

6. E-Z fast wedge clamping was designed to change tools quickly.

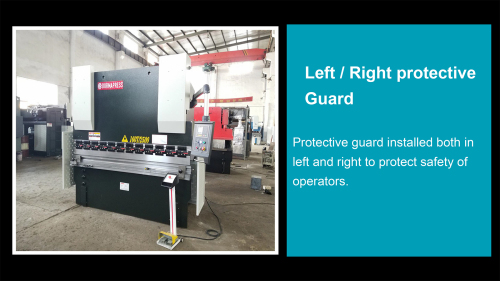

7.Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

Standard Equipment:

1.System Intermediate Upper clamps with Anti Wedges

2.Plate Support Arms

3. Powered Depth Axis

4. Backstop

5. Light guards

6. Top and Bottom Tooling

7. Estun E21 NC control

8. Germany Bosch-Rexroth Hydraulic

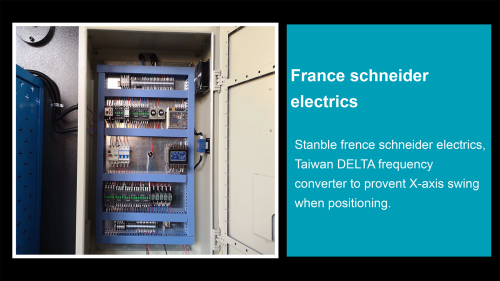

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Squaring Arm and Front Support Arms

12. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

13. Side guard is standard meeting CE regulations

RFQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

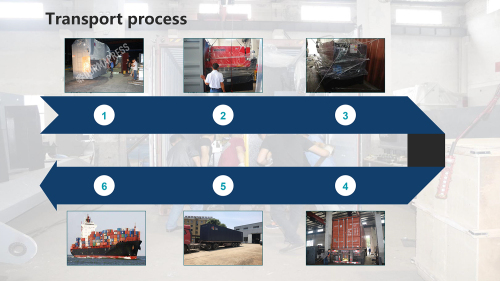

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

.jpg)

.jpg)