|

Maanshan Durmapress Machinery Technology Co., LTD

|

welding automatic machine automatic rebar cutting and bending machine

| Price: | 13900.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working

Ma'anshan Durmapress Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

1.Main Features

1) hydraulic drive, the machine at both ends of the cylinder placed in the slider, direct drive sliding work.

(2) the use of mechanical block structure, stable and reliable.

(3) slider stroke maneuver fast tune, manual fine-tuning, counter display.

(4) the use of all welded structure, with sufficient strength and rigidity.

(5) The slider synchronization mechanism uses the torsion axis forcing synchronization.

(6) wedge-shaped deflection compensation mechanism to ensure a higher bending accuracy

2. Main Configuration

Estun E200P controller

Controller controls and adjusts Y-axis and X-axis

Servo drive and control positioning of X-axis and Y-axis

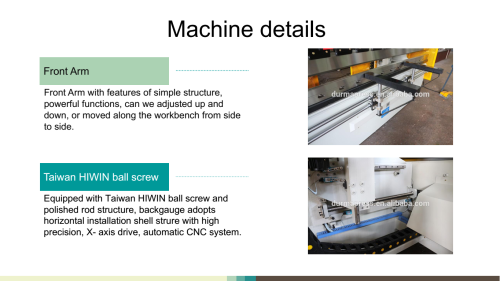

Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

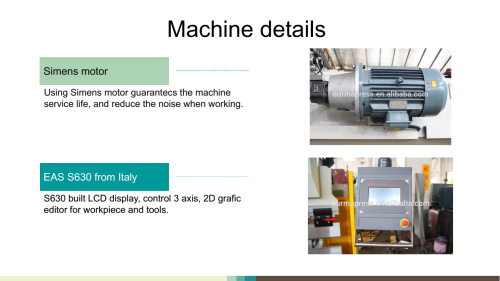

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

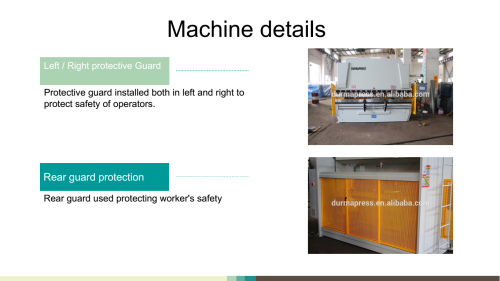

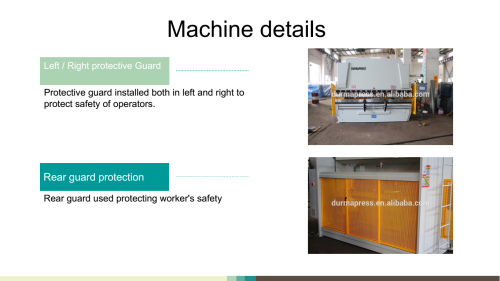

3. Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

Front Finger protection ( safety light curtain )

South Korea KACON pedal switch ( safety grade 4 )

Back metal safeguard, CE standard

Safety relay monitor pedal switch, safety protection

Safety standard ( 2006/42/EC)

4.ESTUN E200 Controller

LCD display,240x128;

A multi-stepprogramming to run automatically

Positioning in a row;

Automatic way to avoia the backgauge with expencted workpieces interference;

One-way location,the elimination of screw drive space;

Duck/British system is available;

Chinese and English menu operation;

Automatic compensation of the location;

Adequate storage space for th processing procedures;

Memory funcation of power off action

5.WC67K 125T 2500 Press Brake Specification

Model | WC67K 125T 2500 |

Normal Pressure | 125T |

Worktable length | 2500mm |

Distance between holes | 2120mm |

Depth of throat | 320mm |

Ram travel | 125/150mm |

Max opening height | 370/400mm |

Main power | 7.5kw |

Weight | 6000KG |

Overall dimension | 2800*1600*2400mm |

1.Standardization of Service "212" |

| 2: response in 2 hours |

| 1: provide solution in 1 day |

| 2: solve complaint in 2 days |

| 2.Installation Service |

| Installation Services are available with all ERMACO machines. We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel ) |

| 3.Training Service |

| Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. |

| 4.Quality Guarantee |

| We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. |

| We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments. |

| Machine warranty is 3 year. We offer flexible extended warranties if needed. |

FAQ:

How about your machine quality? We are worry about the quality.

RE:Byfo company is a mature brand in CHINA,through our 19 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there aremetal plate industry ,there are Brillante machines.And where there are our machines,there are good reputation and terminal user satisfaction.

Whether the machine price can be more discount?

RE:1.BYFO always provide high quality machine,as we know ,oversea market is more important and difficult than domestic market because of communication time costing after sales,So always,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients.

RE:2. we are sure to provide quality=price and price=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.

.jpg)

.jpg)