|

Maanshan Durmapress Machinery Technology Co., LTD

|

automatic metal sheet bender machine

| Qty (Set/Sets) | Unit Price (9900.0~9920.0 USD) |

| 1 | 9920 |

| 2 + | 9900 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

Durmapress Founded in 2006,Maanshan Durmapress CNC Machinery Co.,Ltd is located in

the Maanshan city ,Dangtu County,close to Nanjing Airport. Our geographical position is

superior and the transportation is very convenient. Our company covers an area of 160 acres

with the registered capital of 32,000,000 Yuan. We have more than 320 employees, including

all types of engineering and technical personnel, serving the company R&D, production, and

customers' service. At the same time, we have our own sales companies in each major and

medium city.

Our main products are:CNC Press Brake,Guillotine Shearing Machine,Ironworker,power press ,

and rolling machine these sheet metal processing equipmments.we are using advanced

technology from German,Japan,and Italy,France and so on.

The whole structure of the hydraulic press brake:

Welded structure: the stress of the welded parts can be eliminated by vibration; so this

forging press gives high accuracy.

Frame: consists of right and left wall boards, working table, oil box, slot steel and etc.

The stress of the welded parts can be eliminated by vibration. The machine enjoys high

accuracy and high strength and can be transported easily.

High accuracy,high efficiency,simple and convenient operation,good performance, favorable

price and best service.

1. Hydraulic system:

Adopt integrated hydraulic control system, more reliable

Be installed at the top of the oil box, which can assure that the cylinder is always full of oil

when the slide is moving down at high speed

Consist of motor, oil pump and valve groups

Complete working cycle can be realized through the control of hydraulic valve.

The working pressure at the right side of the wall board can be adjusted by the remote adjustment

valve

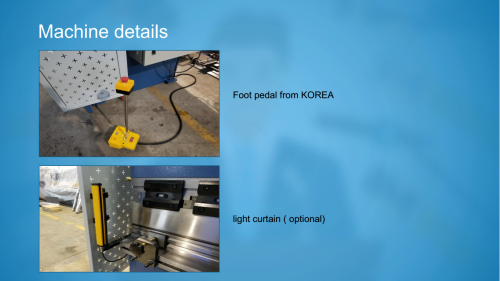

2. Protective fence and the safety interlock

Protective fence and the safety interlocker to ensure the operation safety. Power supply switch

that is set in the electric box will be automatically turned off when the box's door is opened or

the fence is turned up. Protecting barrier with safety interlocker is mounted on the back of the

machine. Another, there are travel limit protection and foot pedestal mounted emergency off

switch.

3.Synchro control system:

Slide syncho system: adopt steel torsion bar synchro system, simple in structure and high

in accuracy

2 ends of slide has 2 synchro fork which make,The system uses upper die compensation to

improve the brake precision.

Adopt upper die compensation to improve the brake precision

4. Sectional Ram Clamp Bars:

Separate sectional clamping bars are supplied as standard equipment in order to securely

fasten short dies, as well as standard length tooling. Unique crown correcting device is standard.

5. Advance technology and procedures:

This metal machining tool is a kind of steel torsion bar synchro press brake. -Electronic control

of back gauges and ram stroke, data displayed and manual setting

Process of cylinder and sealing component:

Cylinder: no.45# steel treated, inner holes fine machined and extruded.

Valve rods: no.45# steel treated, nickel and phosphorous coated outside.

1.Main Features

1) hydraulic drive, the machine at both ends of the cylinder placed in the slider, direct

drive sliding work.

(2) the use of mechanical block structure, stable and reliable.

(3) slider stroke maneuver fast tune, manual fine-tuning, counter display.

(4) the use of all welded structure, with sufficient strength and rigidity.

(5) The slider synchronization mechanism uses the torsion axis forcing synchronization.

(6) wedge-shaped deflection compensation mechanism to ensure a higher bending accuracy

2. Main Configuration

Estun E21 NC controller

Controller controls and adjusts Y-axis and X-axis

Servo drive and control positioning of X-axis and Y-axis

Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

3. Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

Front Finger protection ( safety light curtain )

South Korea KACON pedal switch ( safety grade 4 )

Back metal safeguard, CE standard

Safety relay monitor pedal switch, safety protection

Safety standard ( 2006/42/EC)

FAQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell

us your nearest port or address with postcode. we have reliable shipping agent to insure

the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

.jpg)

.jpg)