|

Maanshan Durmapress Machinery Technology Co., LTD

|

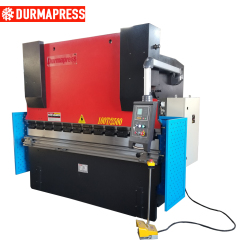

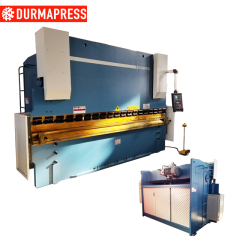

Hydraulic press brake for bending steel plate WC67Y

| Price: | 5800.0 USD |

| Payment Terms: | T/T,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working pr

Established in 1991, Jiangyin Metallurgy Hydraulic Machinery Factory is located in Jiangyin, an economic leading city in eastern China. As a professional manufacturer of hydraulic machineries, our company integrates with capabilities of design, research, development and production.

After 25 years of rapid development, we have become a well-known factory in domestic metal scrap recycling industry. Our products metal baler are widely applied to the industries of metal recycling, foundry and metallurgy and are well received. Currently, we have two plants, the machining plant and the assembling plant, cover an area of 12000 square meters. There are more than 150 staff members, 17 professionals among them. And we have obtained 12 national patents so far.

Our main products are as follows, namely, hydraulic briquetting press, hydraulic metal baler and hydraulic alligator shear. Our products are not only popular in China, but also have market shares in more than 20 Countries, for example, India, Russia, Ukraine, Japan, Thailand, Kuwait, Vietnam, Indonesia, Canada and Columbia.

For the sake of the benefits of our new and old customers, we will ceaselessly improve the product quality as much as we can.

Our factory was awarded the quality control approval certificate ISO9001, from material test, process inspection to final test complete quality control system is already in place.

Main Features

●CNC Series machines redesigned based on users preferences to become a unique machine with its individual electronic and mechanical features.

●CNC Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum level

●with its user friendly CNC controller and low cost hydraulic maintenance.

● New CNC is exactly what you need for your production where complicated, sensitive, single or multiple bends on high speed are paramount.

● High quality and repetitive bending is obtained by using synchronized cylinders and valves.

●Automatic utilisation of all axes on startup.

●Rigid upper beam runs on 8-point bearings with bending precision of 0,01 mm.

● Well-known top and bottom tool brands are long lasting hardened and provide precise bending.

● All Bamboo machines are designed using SOLID WORKS 3D programming and made with enhanced ST44-1 quality steel using the latest Technology.

Product Type: | CNC Synchronized Hydrualic Press Brake |

Bending Material: | Metal/ Stainless Steel /Carbon Steel /Aluminum |

Blade Material | 9 Crsi/6CrW2Si(Optional) |

Backgauge range | 20-1000mm(Optional) |

Safety Standard | Europe CE/South America NR12 |

Control Axes: | Y1 + Y2 + X + W-axis Crowing( Standard) |

Controller | Delem DA66 from Holland (Up to 8 Axis) |

After-sales Service | Engineers available to service machinery overseas |

Punch and die: hydraulic plate press brake, cnc hydraulic plate press brake machine

1. A set of upper and lower die attached with machine.

2. Normally, the short moulds in sectional form are used to splice for desired length with high precision, fine interchangeability,

and convenience for dismantling and installation. In particular, the connecting section to the upper die is equipped with wedge-shape

regulating unit, which, as compensation, may raise the work precision of work pieces in full length.

3. The lower dies are processed in different V-gutters to make operators select conveniently and it is equipped with lower die standing

up structure, only need to put lifting roller chain on the slide lifting ear and lower die lifting ear, loose top formwork to raise slider to

turn lower die then to select the location surface of V-gutter.

Hydraulic System

The hydraulic adopts the integrated, which helps to reduce piping connection, eliminate oil leakage, improve the work stability, and beautify the machine appearance, the inner engaged gear pump manufactured by a famous Germany company is used to reduce the system noise and extend the service life for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Our services:

1.) we can send our engineer to your site and do the training for your men. you will only bear the cost for our engineer's air ticket,visa,accommodation,eating and transportaion in your country

2.) You can send your men to our factory. we will teach them how to op erate the machine with no training charges

3.) Actually there is another cheap and easy way to choose. every machine leave our factory with one book of operation manual.You can first read through the manaul,and get familiar with the machine. Then we can get a video call,and teach you on-line how to o perate the machine.

Apart from above training course,we also provide 2 year warranty for all the easily broken part of the machine.

WHY CHOOSE US

Q1:How Can i calculate the Machine Capacity?

A: Just send me the Max thickness and Length .Engineer will tell us the capacity directly

Q2:How about the machine warranty?Is the whole machine?

A:We canoffer 4 years warranty for the following parts :

--Hydraulic System with pump and Valve

--Hydraulic Cylinders

--Electric units

--Hydraulic Cylinders

--Gasket Ring( We will send you extra with the machine also )

--Tube Connector

--Control Button

--Limit Switch

--Controller

During the warranty period we provide any accessories for free

Q3: What is your MOQ?

A:To let more customer know our quality, we accepty trial order service,So the MOQ is 1 set.

Q4: what is your delivery time?

A:We supply prompt delivery time:25-30days.

Q5:What kind of payment does your company support?

A:T/T, L/C , Cash, Western Union are all accepted

.jpg)

.jpg)