|

Maanshan Durmapress Machinery Technology Co., LTD

|

100T3200 used hydraulic press machine

| Price: | 9500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working

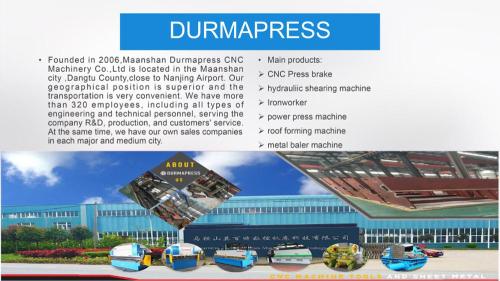

DURMAPRESS hydraulic machinery factory located in Jiangsu province China, closed to Shanghai city and transportation is very convient. Our factory took the lead in passed authentication of the ISO9001:2008 quality management system and CE certificate. A factory specialized in the production of hydraulic press brake and shearing machine. All along, the company products with exquisite design, reaonable price, excellent quality and efficient after-sales service and technical support, received the affirmation of customers at home and abroad, sell well in more than 20 domestic provinces, cities and districts, and exported to the United States, Japan, Russia, European Union, southeast Asia, the Middle East and other countries.

Competitive Advantage:

1. CE, ISO Certification.

2. We can supply KLT brand or OEM for clients.

3. We can supply product line solution according to clients' requirements.

4. Independent electrical control with PLC and TPC.

5. Adopted Rexroth Hydraulic valve system/Siemens Motor to ensure that the hydraulic system is not leaking.

6. The pressure, stroke, and time of pressure maintaining can be regulated.

7. High quality and performance with good price.

8. Safe and stable operation.

9. Support 7*24 remote service or locate service.

10. Supply maintenance service all life.

Main performance :

1. Steel-welded construction, vibration to eliminate stress with high strength and good rigidity

2. Adopted ATOS valves from Italy.

3. Fitted with manual operation ,semi-automatically operation , full-automatically operation three working mode.

4. Blade clearance adjusted by number marked plate ,quickly ,accurate ,convenient

5. The edge of upper knife carrier is forming into a curved surface to ensure the clearance identity between upper and lower blades during the shearing process.

6. The upper carrier derived by right and left oil cylinders and with the support of fulcrum eccentric sleeve to fulfill shearing function.

7. It has also equipped with light to overlapping the draw line on the plate .

8. Main electrical parts adopted SCHNEIDER

Guarantee Terms:

Complete service by free of charge within 13 months after B/L date Technical service will be given forever at any time. Any questions during operation, can contact us freely by email, or contact on line by Skype, WhatsApp, etc. Also can talk face to face during fairs. You will get response within 20 hours.

hydraulic steel stainless sheet metal bending machine sheet bender folding machine folder pan brake machinery

Standard Features

| 1. Hydraulic clamp and unclamp from foot switch, this allows one man to operate machine and hold material in both hands; Clamping is limited to 10mm increments for safety. Unclamp from foot switch. |

| 2. Rapid head adjustment allows easy change different size material, by moving the handles, Adjustable to suit special jobs . |

| 3. Fingers clamp blade are high carbon steel, Apron blade high tensile steel. |

| 4. Electrics low 24 volts foot switch. Overload protected. |

| 5. Clamping provided by large rams, Oil delivered to rams through steel pipes this is to minimize expansion of hydraulic hose when working at full capacity. |

| 6. Unclamp is controlled, to allow the operator to regulate the open height |

| 7. Bed head and apron are unique design, to provide maximum strength. To give a straight fold. |

| 8. Automatic and manual control. In auto cycle after clamping start auto a[rpm will come up to angle set, then apron will go down and the head will unclamp to amount set by operator. |

| 9. Electric components is.SIEMENS |

Specifications

| Monolithic steel-welded construction |

| Hydraulic system drive, |

| CNC system,high precision. Easy to operate Function and characteristic: The machine tool is full welded-steel plate construction. After vibration aging treatment, the deformation is minor so that the accuracy can be ensured. Machine is hydraulically powered. It is low energy construction, easy to maintenance and durable in use. Upper acting die is sub-portfolio with the open height up to 110mm and suitable for producing disk, box like workpieces. The bending angle and back gauge is controlled by numerical control system, rapidly and accurately |

Using a combination of blowing and automatic folding kinfe technology. Adopting large-screen liquid crystal display intelligent control system.The use of teo-wheeled two-speed system,regardless of the size of the comptroller line setting a precise folding. The running speed adjustment range,can be matched with a variety of ironing machine.With self-diagnostic function,single-link signal detectiontechniques and improve the safety protection system.The control computer by realy output port without intermediate realy accurate and easy maintenance.With automatic elimination of static switching devices and safety protection. |

Technical Training

Tenroy company is responsible for the user operator training and also we will provide a training software to you.

Quality Assurance

Our company is responsible for the maintenance during the use period (damage that caused by improper operation, the user should bear the repair charge). Warranty is 12 months after the end debugging.

Our service

1.Installation Service

We dispatch technician to customer's factory for installation and preparation of machine operation. ( Customers only need to pay for the air fare and hotel .)

2.Training Service

Our technicians are available to your factory and provide training on how to use the machine. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the air fare and hotel. )

3.Quality Guarantee

We arrange final test before shipment. After making sure machine is in the best condition, we make shipment.

Machine warranty is 5 years.

Packing & shipping

FAQ:

1.How about your automatic portable press brake quality?

Better is a mature brand in CHINA,through our many years research in technology. our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Better machines.

2. What's your after-sale service?

Better provide oriented after-sales service including the oversea engineers training available and also international dealer center for any emergency guidance.We have established worldwide network to guarantee our timely response for your any demand no matter where are you.

We welcome engineers from your side to learn the technical design and normal maintenance here,this will help your easy in understanding and helpful if you need to be our dealer.

3. How to operate your automatic portable press brake?

Don't worry,we have our company own CD/Manual to show you along with the machine.So you can learn this from the existing documents to deepen your knowledge and understanding. Anyhow there are another way is through internet video face to face for machine teaching, because of the high development in internet,the world has become smaller and you can easy catch us if any assistance needed

.jpg)

.jpg)