|

Maanshan Durmapress Machinery Technology Co., LTD

|

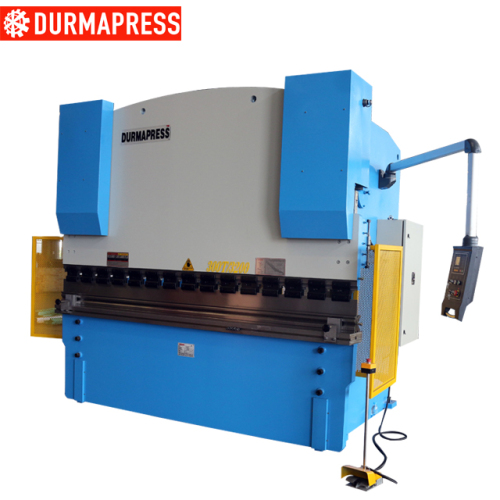

WC67Y 300T/3200 hydraulic bending machine

| Qty (Set/Sets) | Unit Price (14900.0~25000.0 USD) |

| 1 | 25000 |

| 2 + | 14900 |

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,CPT,EXW |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

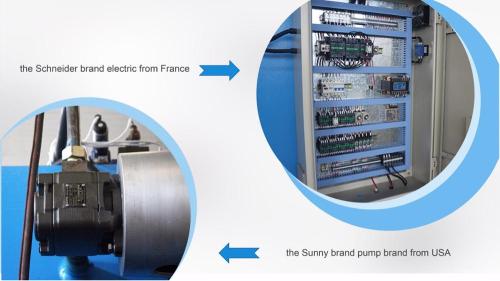

Standard Equipment ( Sunny pump , Schneider electrical , Bosch-Rexroth hydraulic system and hydraulic pump , Siemens Motor ).

Reliable performance Hydraulic press brake in Maanshan,Anhui,WC67Y 125T/3200

Technical parameter

Name of the product: Reliable performance Hydraulic press brake in Maanshan,Anhui,WC67Y-125T/3200

Model | Nominal Force | Bending Width | Distance of Column | Open Height | Throat Depth | Ram Stroke | Stroke Adjustment

| Table Length | Motor Power | Dimension/mm | |

KN | MM | MM | MM | MM | MM | MM | MM | Kw | (L*W*H)(MM) | ||

100/2500 | 1000 | 2500 | 2050 | 330 | 320 | 150 | 120 | 850 | 7.5 | 2600×1400×2300 | |

100/3200 | 1000 | 3200 | 2600 | 330 | 320 | 150 | 120 | 850 | 7.5 | 3300×1400×2380 | |

100/4000 | 1000 | 4000 | 3200 | 330 | 320 | 150 | 120 | 850 | 7.5 | 4100×1400×2480 | |

100/5000 | 1000 | 5000 | 4100 | 330 | 320 | 150 | 120 | 850 | 7.5 | 5100×1500×2580 | |

125/3200 | 1250 | 3200 | 2600 | 330 | 320 | 150 | 120 | 850 | 7.5 | 3300×1400×2380 | |

125/4000 | 1250 | 4000 | 3200 | 330 | 320 | 150 | 120 | 850 | 7.5 | 4100×1400×2480 | |

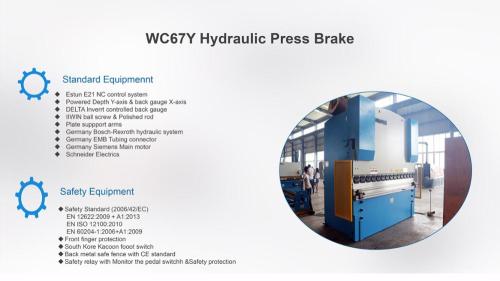

Synchronization

The electric-hydraulic servo system can control the synchronization of cylinders for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender. Combined with optical curtain of international standard, the fully closed loop control is formed with high bending and repetitive positioning accuracy for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Compensation

The CNC cylinder deflection auto compensation system helps to prevent the deformed sliding block from affecting the workpiece quality and ensure its good linearity and bending angle WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender. The compensation id adjusted automatically by the CNC system, both convenient and accurate for WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Feeding System

There can be 6 axels when equipped the inward CNC system for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

The hydraulic adopts the integrated, which helps to reduce piping connection, eliminate oil leakage, improve the work stability, and beautify the machine appearance, the inner engaged gear pump manufactured by a famous Germany company is used to reduce the system noise and extend the service life for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

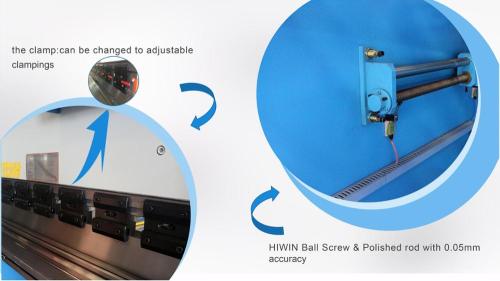

Tooling

The die sections have different lengths, which can be combined with a certain width to meet the processing requirements of special work pieces for for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

FAQ

How about your machine quality? We are worry about the quality.

RE:Wanli of Pacific is a mature brand in CHINA,through our 14years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Brillante machines.And where there are our machines,there are good reputation and terminal user satisfaction.

Whether the machine price can be more discount?

RE:1.Wanli of Pacific always provide high quality machine,as we know ,oversea market is more important and difficult than do mestic market because of communication time costing after sales,So always,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients.

RE:2. we are sure to provide quality=price and price=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.

Provide Pre-sales Consultant & On-purchase service 8 hr × 6 days per week

1. Reply within 24 hours

2. Provide relevant product information

3. Answer questions if request

4. Give technical suggestion

Provide After-sales service 24hr × 7days per week

1. Test the machine before shipment

2. Provide technical guidance relate to use the machine

3. Supply one-year warranty period for the machine

4. Provide the spare parts at cost price after warranty period

5. Collect the feedback for the machine working

6. Provide long-term technical assistance.

Our Services

1.) we can send our engineer to your site and do the training for your men. you will only bear the cost for our engineer's air ticket,visa,accommodation,eating and transportaion in your country

2.) You can send your men to our factory. we will teach them how to op erate the machine with no training charges

3.) Actually there is another cheap and easy way to choose. every machine leave our factory with one book of operation manual.You can first read through the manaul,and get familiar with the machine. Then we can get a video call,and teach you on-line how to o perate the machine.

Apart from above training course,we also provide 2 year warranty for all the easily broken part of the machine.

.jpg)

.jpg)