|

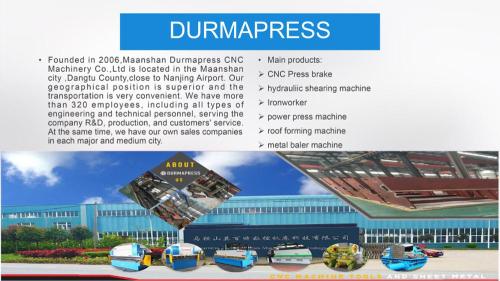

Maanshan Durmapress Machinery Technology Co., LTD

|

100T2500 hydraulic plate bending machine price

| Price: | 9500.0 USD |

| Payment Terms: | T/T,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working

Established in 2001, Jiangyin Metallurgy Hydraulic Machinery Factory is located in Jiangyin, an economic leading city in eastern China. As a professional manufacturer of hydraulic machineries, our company integrates with capabilities of design, research, development and production.

After 25 years of rapid development, we have become a well-known factory in domestic metal scrap recycling industry. Our products metal baler are widely applied to the industries of metal recycling, foundry and metallurgy and are well received. Currently, we have two plants, the machining plant and the assembling plant, cover an area of 12000 square meters. There are more than 150 staff members, 17 professionals among them. And we have obtained 12 national patents so far.

Our main products are as follows, namely, hydraulic briquetting press, hydraulic metal baler and hydraulic alligator shear. Our products are not only popular in China, but also have market shares in more than 20 Countries, for example, India, Russia, Ukraine, Japan, Thailand, Kuwait, Vietnam, Indonesia, Canada and Columbia.

For the sake of the benefits of our new and old customers, we will ceaselessly improve the product quality as much as we can.

Our factory was awarded the quality control approval certificate ISO9001, from material test, process inspection to final test complete quality control system is already in place.

Ma'anshan durmapress Machinery Technology Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

We sincerely wish all the friends work together for a common development!

1. Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

2.Hydraulic synchronised positive stop design,and by Etsun NC programmable controller assuring accurate repeatability &ease of use.

3.Integrated hydraulic system(Bosch-Rexroth form Germany)allowing rapid approach switching automatically to slow bend.

4.Inverter with E21 NC System operated back gauge with quality support fingers also with vertical adjustment

5.Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays.

6.Safe fence and the electric inter locker have been designed for the machine to ensure the operation safety.

Features

1.Special numeric-control system is fitted with mainframe of the bending machine.

2.Multi-work-step programming function is able to achieve an automatic operation and continuous positioning of multi-step procedures,as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3.The machine is provided with bend counting function,for a real-time display of processing quantity and power-failure memory of positions of stopper and gliding block,as well as procedures and parameters.

4.Imported ball bearing lead screw and linear guide rail are used for rear stopper,to ensure the positioning precision of rear stopper,for processing precision of machine to be higher.

Standard configuration

1.Standard two axis control (Y, X).

2.Mechanical torque synchronization.

3.Domestic famous hydraulic integrated system.

4.Siemens or Schneider low-voltage electrics.

5.Inverter control motor operation.

6.Imported seals.

7.Ball screw back gauge operation control.

8. Standard upper and lower tools (produced by our own company).

9. Front material supporting frame.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ:

Q1: How can I get a quotation?

A1: Pls tell us the machine you need, including quantity, raw materials and other requirements.

Q2: After I buy the machine, what will you do if I don't know some of the function?

A2: We will show you how to use the machine perfectly. Technical support and the video is available.

Q3: What can I do if the machine troubled after I buy it?

A3: We provide completely after sales service, and our engineers are available to service machinery overseas.

Q4: Will you show me how to install the machine?

A4: Certainly, we will enclose the production specification with the machine, and we could provide the video online to you, and our engineers are available to service machinery overseas.

WE PROVIDE THE FOLLOWING SERVICE AFTER RECEIVING YOUR ORDER:

1) During the production we arrange the samples lot as per the customer requirement, then we send the samples photo and samples to the customer to approval.

2) After the production finish we send the samples to customer to check, after customer approval we ship the goods to the customer.

3) After customer received the goods we check and take the necessary follow-up with the customer in order to solve some small mistakes in next lot.

PACKING DETAILS:

CARTONS - Export worthy Packing

DELIVERY:

TNT, UPS, DHL, FedEx, Air shipment, Sea shipment^

.jpg)

.jpg)