|

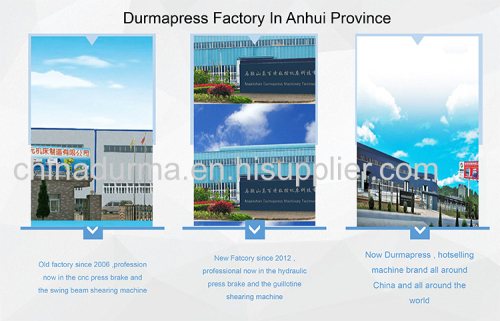

Maanshan Durmapress Machinery Technology Co., LTD

|

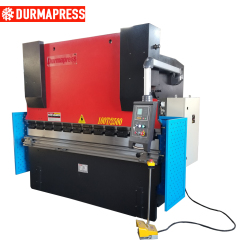

63T2500 bending machine with press brake

| Price: | 7900.0 USD |

| Payment Terms: | T/T,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working pr

Maanshan Durmapress Machinery Technology Co;Ltd

We can supply various specifications of Hydraulic Amada Press Brake,Plate Shearing Machine & Rolling Machine,with or without CNC,power press machine,west baler machine and packing machine and the blades for the machines,according to customers' requirements.

We are also professional manufacturer of Punching Machine, Hydraulic Press, Iron Worker, Ventilation Equipment,Machine Tool Fittings, Bending Machine Dies, Punch Dies & Cutting tools.

All of our hydraulic cnc brake presss have passed the ISO 9001 Quality System Certificate and CE Certificate

Model: serialWC67Y-

1. The frame is steel-welded construction, vibrating to eliminate stress, with high strength and good rigidity.

2. Forcing-torsion shaft maintains the synchronization of both cylinders with high precision.

3. Mechanic stop nuts ensure stable and reliable positioning accuracy.

4. The ram is driven by hydraulic system with two cylinders. Working pressure could be adjusted stepless and the noise of machine is lower.

5. The stroke of ram and back gauge could by adjusted through motor; Also it could be adjusted by hand wheel for fine position. The value adjusted could be displayed on numerator.

6. Main sliding parts such as cylinders, piston rod, guide way, are all treated with wear-resistance.

7. There are slanting wedges (compensation units) installed on the top of tools. They could be adjusted by hand to meet the accuracy requirements of work piece.

8. Deflection compensation unit is adopted under worktable for the machine above 250Tons.

9. Full machine is guarded with safety guard with interlocker to prevent the operator from injured.

OPTIONAL:

1 two-hand control foot pedestal device

2.it is possible for special tooling with different lengths to bend the closed frame workpiece

3.any tailor-made are available on request.

Synchronization

The electric-hydraulic servo system can control the synchronization of cylinders for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender. Combined with optical curtain of international standard, the fully closed loop control is formed with high bending and repetitive positioning accuracy for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Compensation

The CNC cylinder deflection auto compensation system helps to prevent the deformed sliding block from affecting the workpiece quality and ensure its good linearity and bending angle WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender. The compensation id adjusted automatically by the CNC system, both convenient and accurate for WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Feeding System

There can be 6 axels when equipped the inward CNC system for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

The hydraulic adopts the integrated, which helps to reduce piping connection, eliminate oil leakage, improve the work stability, and beautify the machine appearance, the inner engaged gear pump manufactured by a famous Germany company is used to reduce the system noise and extend the service life for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Tooling

The die sections have different lengths, which can be combined with a certain width to meet the processing requirements of special work pieces for for our WE67K Hydraulic CNC bending machine, hydraulic Press Brake, CNC Bender.

Our Services

The after-sale service work is an important part of our marketing and sales work

The quality of service provided will not only influence the company credit,

But also closely relate to the safely running of the equipments.

In order to maintain the good reputation,yaou company will strictly observe relevant national regulations about produce-quality law and provide high quality products with the principle of hospitable reception,enthusiastic service,quick response and prompt resolution.we will conscientiously implement the after-sale service work in full-scale,and make commitment to our dients as follows:

1)all products are customized according to customer's requirements,and loyalty to customer.

2)Once found size and quality problems,pls contact us in time,we will solve the problem for customers in the first time,strictly in accordance with regulations of the company

3)Once found you get loss because of our fault,all charges shall be borne by yaou company.

4) The loss caused by improper use by the customer,shall be borne by the yours,but company should offer technical assistance to help customers to solve practical problems

5)We are professional oilfield equipment supplier in China more than 10 years.

6)Backup skillful and experienced sales team would help you get an efficient solution.

7)We have our own logistics company and this could guarantee the service after sales

Size | 3500 (L) *1850 (W) * 2650 (D) |

Weight | 9500Kgs |

Packaging Details | 1.The bottom of the wooden case has firm iron jack,convenient to Handling and transport. |

.jpg)

.jpg)