|

Maanshan Durmapress Machinery Technology Co., LTD

|

Gold Index: 57509

used hydraulic press machine

| Price: | 8900.0 USD |

| Payment Terms: | T/T,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working

| Main Features: |

| 1. Machining accuracy is high: backgauge repositioning accuracy of 0.1mm ram repositioning accuracy of 0.1mm. |

2. Large processing range: This product slider stroke is 265mm, closed height is 480mm, column distance is 2700mm, backgauge X axis stroke is 500 mm; compared to ordinary products, the products can less you trouble of the following accumulation |

| 3. This product adopts the main motor with large power, large flow pump, it can realize adjustable speed, fast speed can easily reach 220mm/s |

| 4. This product can reduce the heat generation, hydraulic oil temperature is low, the maximum limit to reduce the damage to the hydraulic components, to extend the service life of the product |

| 5. Electro-hydraulic system is adopted to control dual cylinders to get high synchronized controlling accuracy, high bending accuracy, and repositioning accuracy |

| 6. Hydraulic auto compensation system is adopted to eliminate the effect of the deformed sliding block during bending which may affect bending quality. |

| 7. Multi-functional backgauge which can be expanded into 6 axes, i.e., X1 and X2 axes for back and forth, R1 and R2 axes for up and down and Z1 and Z2 for left and right. The workpiece bending can be realized flexibly. |

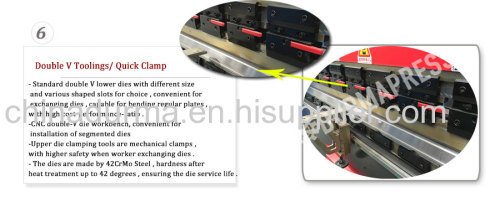

| 8. Segmented punch can be combined with certain length according to the bending requirement of special workpiece. |

| 9. CNC system adopts Delem DA66T/ DA52S CNC system. |

| Monolithic steel-welded construction |

| Hydraulic system drive, |

| CNC system,high precision. Easy to operate Function and characteristic: The machine tool is full welded-steel plate construction. After vibration aging treatment, the deformation is minor so that the accuracy can be ensured. Machine is hydraulically powered. It is low energy construction, easy to maintenance and durable in use. Upper acting die is sub-portfolio with the open height up to 110mm and suitable for producing disk, box like workpieces. The bending angle and back gauge is controlled by numerical control system, rapidly and accurately |

Using a combination of blowing and automatic folding kinfe technology. Adopting large-screen liquid crystal display intelligent control system.The use of teo-wheeled two-speed system,regardless of the size of the comptroller line setting a precise folding. The running speed adjustment range,can be matched with a variety of ironing machine.With self-diagnostic function,single-link signal detectiontechniques and improve the safety protection system.The control computer by realy output port without intermediate realy accurate and easy maintenance.With automatic elimination of static switching devices and safety protection. |

Technical parameters:

Type | WC67K-80/3200 |

CNC system | DA41 |

Nominal pressure | 800KN |

Length of table | 3200mm |

Distance between columns | 2360mm |

Slide stroke | 100mm |

Max. opening height | 320mm |

Throat depth | 250mm |

Main motor power | 5.5KW |

| 1. Standard Service: |

Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. |

| 2. Installation: |

Our factory can send our engineer to the customer's factory install, commission and training freely .The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely. |

| 3. Quality Guarantee: |

Our guarantee time is 14 months from B/L Date ,If any component is damaged during guarantee time,we can send the component to the customer By DHL,TNT freely. |

| 4. Order Processing: |

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Maanshan Durmapress Machinery Technology Co., LTD [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ma'anshan

Province/State: Anhui

Country/Region: China (Mainland)

You May Like:

Product (600)

- press brake and shearing machine Tooling (10)

- punching machine power press (51)

- Pneumatic Punching Machine (54)

- WC67Y/K Press Brake (210)

- QC11Y/QC12Y Shearing Machine (136)

- Plate Rolling Machine (11)

- Hydraulic ironworker machine (46)

- V Cutting Machine (36)

- Angle Hydraulic V Notching Machine (34)

- HAVC Duct machine (10)

- Press brake mould and Shearing Blade (2)

.jpg)

.jpg)