|

Maanshan Durmapress Machinery Technology Co., LTD

|

Gold Index: 57509

cnc press brake with nc controller

| Qty (Set/Sets) | Unit Price (5900.0~6000.0 USD) |

| 1 | 6000 |

| 2 + | 5900 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

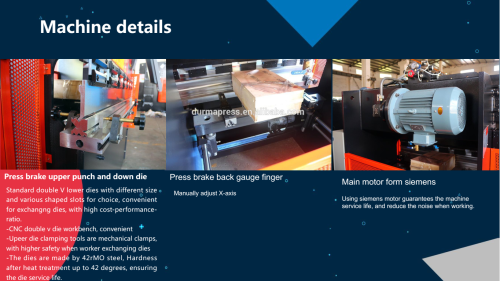

Electric adjustment, manual fine adjustment, and digital display for backgauge distance and stroke of up ram.

Main features:

1) Overall welded and processed structure.

2) Closed loop control mode composed of electric-hydraulic servo valve and measure

ruler.

3) Ensure the highest control precision, bending accuracy and repositioning accuracy are

also reach to the highest level.

Back gauge mechanism can be multi-axes controlled.

4) Integrated hydraulic system decreases the pipe connections, oil leakage, and increases

the stability and overall beautifies.

5) Worktable equipped with hydraulic and mechanical compensation to avoid the deformed

upper beam from affecting the quality of the work piece, it is automatically adjusted by the

CNC controller with convenient and accuracy.

6)CNC controller normally uses Holland DELEM, Italy ESA, Swiss CYBELEC, all with

multi-languages.

Technical parameters:

| No | Name | Value | Unit | |

| 1 | Nominal force | 400 | KN | |

| 2 | Worktable length | 1600 | Mm | |

| 3 | Distance between columns | 1200 | Mm | |

| 4 | Throat depth | 200 | Mm | |

| 5 | Slider strokes | 100 | Mm | |

| 6 | The range of slider adjustment | 50 | Mm | |

| 7 | Max open | 300 | Mm | |

| 8 | Worktable height | 800 | Mm | |

| 9 | Max pressure | 26 | Mpa | |

| 10 | Slider stroke speed | Empty load | 7 | Mm |

| At work | 15 | Mm | ||

| Back journey | 50 | Mm | ||

| 11 | Main motor | Model | Y132S-4B | |

| Power | 3 | KW | ||

| Rotating speed | 1440 | r/min | ||

| 12 | Slider adjustment motor | Model | Y132S-4B | |

| Power | 3 | KW | ||

| Rotating speed | 1440 | r/min | ||

| 13 | Back gauge motor | Model | Y80M6B | |

| Power | 0.05 | KW | ||

| Rotating speed | 900 | r/min | ||

| 14 | Axial piston pump | Model | 10MCY14-1B | |

| Flow | 10 | L/min | ||

| Pressure |

31.5 | Mpa | ||

| 15 | Dimension (L×W×H) | Length | 1750 | Mm |

| Width | 1250 | Mm | ||

| Height | 1950 | Mm | ||

| 16 | Machine weight | 2500 | Kg | |

Our Service

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience and

can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the production

is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting and

damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country for

installation and commissioning Buyer pays each engineer 100USD / Day besides the

round-tickets, room and board.

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period,

we will provide spare parts without any charge in case of quality discrepancy caused by us.

If the malfunctions are caused by customers' incorrect operations, we will provide

customers spare parts at cost price. We also can offer flexible extended warranties

according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on

condition of you provide the round-trip air tickets, visa formalities, food and accommodation.

In turn, your engineers can come to our factory for learning the installation, operation and

maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only

guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services

around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or

Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products,

we can offer professional recommendations; reg. non-standard products, we can

offer professional designing.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Maanshan Durmapress Machinery Technology Co., LTD [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ma'anshan

Province/State: Anhui

Country/Region: China (Mainland)

You May Like:

Product (600)

- press brake and shearing machine Tooling (10)

- punching machine power press (51)

- Pneumatic Punching Machine (54)

- WC67Y/K Press Brake (210)

- QC11Y/QC12Y Shearing Machine (136)

- Plate Rolling Machine (11)

- Hydraulic ironworker machine (46)

- V Cutting Machine (36)

- Angle Hydraulic V Notching Machine (34)

- HAVC Duct machine (10)

- Press brake mould and Shearing Blade (2)

.jpg)

.jpg)