|

Maanshan Durmapress Machinery Technology Co., LTD

|

Gold Index: 57509

profile bending machine cnc machine price in india

| Price: | 8900.0 USD |

| Payment Terms: | T/T,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working

Ma'anshan Durmapress Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

Technical parameters:

Type | WC67K-80/3200 |

CNC system | DA41 |

Nominal pressure | 800KN |

Length of table | 3200mm |

Distance between columns | 2360mm |

Slide stroke | 100mm |

Max. opening height | 250mm |

Throat depth | 320mm |

Main motor power | 5.5KW |

2. HYDRAULIC SYSTEM:

It adopts integrated hydraulic control systems which is more reliable and easy for maintenance.

3. SYNCHRO CONTROL SYSTEM:

The slide synchro system adopts steel torsion bar synchro system with very simple structure but very high accuracy. 2 ends of slide has 2 synchro fork which make the slides movement is always parallel to the working table. And this will make the movement effect balanced during operation. The system uses upper die compensation to improve the brake precision.

4. NC control system:

Holland DELEM DA41 system

4.7inch bright LCD display

angle programming

tool programming;

Two speed AC control stepless speed adjustment, enhancing the working efficiency;

imperial /meter unit convert

Auto retract function, avoid interference between plate and backgauge;

Standard Features

| 1. Hydraulic clamp and unclamp from foot switch, this allows one man to operate machine and hold material in both hands; Clamping is limited to 10mm increments for safety. Unclamp from foot switch. |

| 2. Rapid head adjustment allows easy change different size material, by moving the handles, Adjustable to suit special jobs . |

| 3. Fingers clamp blade are high carbon steel, Apron blade high tensile steel. |

| 4. Electrics low 24 volts foot switch. Overload protected. |

| 5. Clamping provided by large rams, Oil delivered to rams through steel pipes this is to minimize expansion of hydraulic hose when working at full capacity. |

| 6. Unclamp is controlled, to allow the operator to regulate the open height |

| 7. Bed head and apron are unique design, to provide maximum strength. To give a straight fold. |

| 8. Automatic and manual control. In auto cycle after clamping start auto a[rpm will come up to angle set, then apron will go down and the head will unclamp to amount set by operator. |

| 9. Electric components is.SIEMENS |

Specifications

| Monolithic steel-welded construction |

| Hydraulic system drive, |

| CNC system,high precision. Easy to operate Function and characteristic: The machine tool is full welded-steel plate construction. After vibration aging treatment, the deformation is minor so that the accuracy can be ensured. Machine is hydraulically powered. It is low energy construction, easy to maintenance and durable in use. Upper acting die is sub-portfolio with the open height up to 110mm and suitable for producing disk, box like workpieces. The bending angle and back gauge is controlled by numerical control system, rapidly and accurately |

Our service

Pre-sales Service

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

After-sales Service

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 1 year

4. Engineers available to service machinery oversea

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

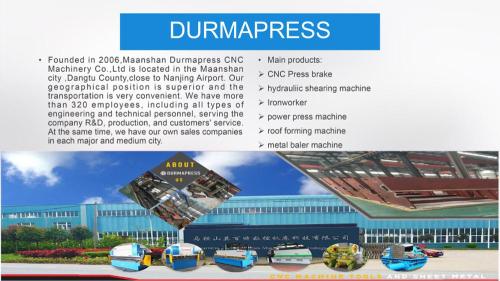

Maanshan Durmapress Machinery Technology Co., LTD [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ma'anshan

Province/State: Anhui

Country/Region: China (Mainland)

You May Like:

Product (600)

- press brake and shearing machine Tooling (10)

- punching machine power press (51)

- Pneumatic Punching Machine (54)

- WC67Y/K Press Brake (210)

- QC11Y/QC12Y Shearing Machine (136)

- Plate Rolling Machine (11)

- Hydraulic ironworker machine (46)

- V Cutting Machine (36)

- Angle Hydraulic V Notching Machine (34)

- HAVC Duct machine (10)

- Press brake mould and Shearing Blade (2)

.jpg)

.jpg)