|

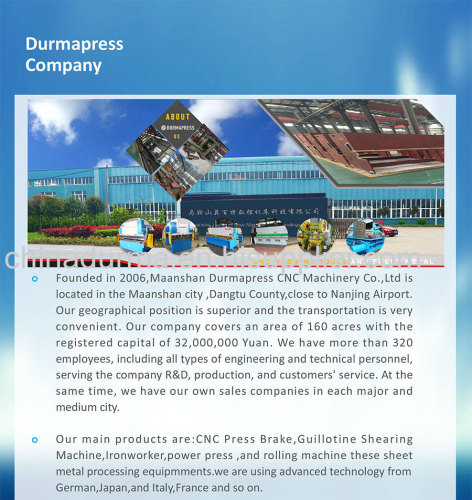

Maanshan Durmapress Machinery Technology Co., LTD

|

CNC Hydraulic bending machine

| Qty (Set/Sets) | Unit Price (5900.0~6000.0 USD) |

| 1 | 6000 |

| 2 + | 5900 |

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Anhui, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

the use of all welded structure, with sufficient strength and rigidity.

2. Main Configuration:

CNC system adopts Netherlands DELEM DA52S

Grating ruler controls depth Y1 and Y2 axis(y1/y2-axis 0.01mm)

Servo motor drive and control X axis(X-axis 0.01mm), manually adjusts R axis up and down, fingers can easily move along the cylindrical guide.

Keep the accuracy between HIWIN ball screw and linear guide within 0.01mm

Front carrier can be adjusted along the linear guide in the worktable direction

Germany Rexroth closed-loop electro-hydraulic servo synchronously controls the system

Germany EMB oil tube connectors

Germany Siemens main motor

France Schneider Electrics

Hydraulic and electrical overload protection

Upper are mechanical fast pinching dies. Lower are double-V quick changing dies

Front finger protection device ( safety light curtain )

South Korea KACON pedal switch ( 4 security grade )

Metal safeguard, CE standard

Safety relay monitors completed with foot switch, safety protection devices

Safety standard(2006/42/EC)

8″wide-frequency colored screen

Max 4-axes control (Y1, Y2, two additional axes )

266MHZ processor, memory capacity of 64M

Die library, 30 upper dies, 30 lower dies

USB memory interface, RS232 interface

Real-time Windows operating platform to ensure the stability of the operation, support instant shutdown

One-page parameters for quick editing, navigation shortcuts

Automatically calculate deflection compensation

Micro switch panel, data editing

Automatically calculate the bending pressure and die safety region

Online operation analysis tool, Diagnostic Dashboard, angle calibration database

3. Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

4. Holland Delem DA52S Controller:

| NO | Name | Value | Unit |

| 1 | Nominal force | 400 | KN |

| 2 | Worktable length | 1600 | Mm |

| 3 | Distance between columns | 1200 | Mm |

| 4 | Throat depth | 200 | Mm |

| 5 | Slider strokes | 100 | Mm |

| 6 | The range of slider adjustment | 50 | Mm |

| 7 | Max open | 300 | Mm |

| 8 | Worktable height | 800 | Mm |

| 9 | Max pressure | 26 | Mpa |

CNC Hydraulic Plate Bending Machine:

Features:

1.Overall welded and processed structure.

2.Closed loop control mode composed of electric-hydraulic servo valve and measure ruler.

3.Ensure the highest control precision, bending accuracy and repositioning accuracy are also reach to the highest level.

4.Back gauge mechanism can be multi-axes controlled.

5.Integrated hydraulic system decrease the pipe connections, oil leakage, and increase the stability and overall beautifies.

6.Worktable equipped with hydraulic and mechanical compensation to avoid the deformed upper beam from affecting the quality of the work piece, it is adjusted automatically by the CNC controller with convenient and accuracy.

7.CNC controller normally uses Holland DELEM, Italy ESA, Swiss CYBELEC, all with multi-languages.

Series Technical Parameters:

| Type | Nominal Force (KN) | Worktable Length (mm) | Vertical Distance (mm) | Throat Depth (mm) | Stroke (mm) | Max Open (mm) | Power (kw) | X-travel (mm) | X-speed |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 5.5 | 500 | 200mm/s |

| 100T/3200 | 1000 | 3200 | 2700 | 400 | 200 | 420 | 7.5 | ||

| 125T/3200 | 1250 | 3200 | 2700 | 400 | 200 | 420 | 11 | ||

| 160T/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 11 | ||

| 200T/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 15 | ||

| 250T/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 15 | ||

| 300T/3200 | 3000 | 3200 | 2700 | 400 | 200 | 420 | 22 | ||

| 400T/4000 | 4000 | 4000 | 3500 | 400 | 320 | 420 | 30 | ||

| 500T/6000 | 5000 | 6000 | 4900 | 500 | 320 | 600 | 37 | 800 | |

| 600T/6000 | 6000 | 6000 | 4900 | 500 | 320 | 600 | 45 | ||

| 800T/6000 | 8000 | 6000 | 4900 | 600 | 400 | 600 | 55 | ||

| 800T/8000 | 8000 | 8000 | 5900 | 600 | 400 | 600 | 55 | ||

| 1000T/6000 | 10000 | 10000 | 4900 | 600 | 400 | 600 | 2×37 | ||

| 1000T/8000 | 10000 | 10000 | 6900 | 600 | 400 | 600 | 2×37 | ||

| 1000T/1000 | 10000 | 10000 | 8000 | 600 | 400 | 600 | 2×37 |

We are producing below ranges of machines:

1.NC/CNC Press Brake

2.NC/CNC Shearing Machine

3,Rolling Machine

4.Iron Worker

5.Power Press

6.Hydraulic Press

Our Services

1.Shearing blades and accessories-Customized to your specifications

In our shearing blades, our focus is on first-class, practical, well-thought-out upper and lower tools. Our tools offer solutions to your application cases - even for complex technical ones.

2.Service package

Basic:we offer you rapid troubleshooting through telephone support and costs for on-site missions are reduced.

Special:Engineers available to service machinery overseas for the necessary maintenance.

Partner:Our located dealers or customers who sell or use our machines are fully behind you,they are our friendly partner and supply good advice to you.

3.Technical Service(After-sale service

Packaging & Shipping

(1)before packing,the machine tool will be testing for 48 hours to ensure all the equipment is 100% qualitied. (2)before loading,stable package,professional and skilled loader reduce damage of product during transport.(3)after loading,our professional documentary staff will follow the order till the product departs from port.

RFQ

*We have our own factory and brand; Our machines can match all the CE standard or more strict ones.

*Quality assurance: 5 years warranty and 100% quality inspection before packing.

*Service:Impeccable after-sale service, and all your problem will be solved within 24 hours.

*Price: Can be negotiable according to the qty.

*MOQ:1 set.

*Howtovisit:You can fly to NanJing LuKou airport directly,you can also take high- speed train to Nanjing South Station from other city in China.We will pick you up in the airport or Train station.

.jpg)

.jpg)