|

Maanshan Durmapress Machinery Technology Co., LTD

|

CNC metal steel hydraulic bending machine press brake

| Price: | 18500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WC67K Series Hydraulic CNC plate bending machine by computer aided design for bending sheet metal with higher labor productivity and higher working

Maanshan Durmapress Machinery Technology Co., Ltd >>>

Our company founded in 1990s is a fixed-point company of Ministry of Construction of China, we are engaging in construction machinery researching, development and manufacturing. Our main products are JZM series electric rolling drum concrete mixers, JS Series Double shaft concrete

mixer,JZR series diesel engine concrete mixers, PLD series aggregate batching and dispensing machines, LSY series cement screw conveyors and HZS/HLS series concrete mixing and batching plant. All these products have won great favor and popularity with more and more customers in

domestic and oversea markets.

| Main Features: |

| 1. Machining accuracy is high: backgauge repositioning accuracy of 0.1mm ram repositioning accuracy of 0.1mm. |

2. Large processing range: This product slider stroke is 265mm, closed height is 480mm, columndistance is 2700mm, backgauge X axis stroke is 500 mm; compared to ordinary products, the products can less you trouble of the following accumulation |

| 3. This product adopts the main motor with large power, large flow pump, it can realize adjustable speed, fast speed can easily reach 220mm/s |

| 4. This product can reduce the heat generation, hydraulic oil temperature is low, the maximum limit to reduce the damage to the hydraulic components, to extend the service life of the product |

| 5. Electro-hydraulic system is adopted to control dual cylinders to get high synchronized controlling accuracy, high bending accuracy, and repositioning accuracy |

| 6. Hydraulic auto compensation system is adopted to eliminate the effect of the deformed sliding block during bending which may affect bending quality. |

| 7. Multi-functional backgauge which can be expanded into 6 axes, i.e., X1 and X2 axes for back and forth, R1 and R2 axes for up and down and Z1 and Z2 for left and right. The workpiece bending can be realized flexibly. |

| 8. Segmented punch can be combined with certain length according to the bending requirement of special workpiece. |

| 9. CNC system adopts Delem DA66T/ DA52S CNC system. |

I Product descripton of the Press brake machine WC67Y-80/3200

Type: PSH-125/3200 (Y1-Y2-X-R-V)

Note: "V" means hydraulic deflection compensation.

II Main configuration of the Press brake machine WC67Y-80/3200

CYBELEC DNC600 CNC control system

Hoerbiger high-performance servo hydraulic system for controlling synchronization.

Grating rulers are equipped on both sides for checking and feedbacking synchronization

The back block is equipped with high-performance servo motor and ball bearing threaded rod

Hydraulic deflection compensation of lower working table is controlled by DNC system

Equipped with standard punch and die

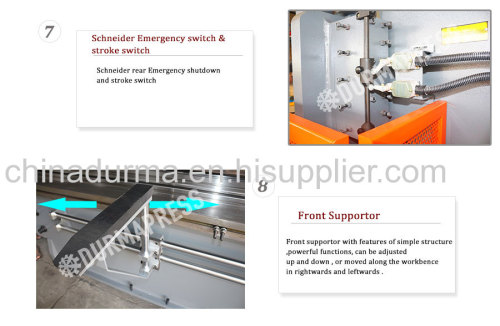

Equipped with front supporting rack

III Main imported components of the Press brake machine WC67Y-80/3200

-- Control system: CYBELEC from Switzerland

-- Hydraulic system: Hoerbiger from Germany

-- Servo motor: Panasonic or Yaskawa from Japan

-- Grating ruler: GIVI from Italy / Austria

-- Joints for oil pipe: EMB from Germany or Parker from USA

-- Seals: Parker from USA

-- Beeline guide rail, ball bearing threaded rods and threaded nuts are from Taiwan

IV Spare parts enclosed with the High quality hydraulic press brake

No. | Name | Quantity | Remarks |

1 | foot-hoof switch | One pc | |

2 | Front supporting rack | One set | |

3 | Foundation bolts | One set | |

4 | Flat washer | Four sets | |

5 | Spring washer | Four sets | |

6 | Nuts | Four sets | |

7 | mat plates | Four sets | |

8 | Grease gun | One set | |

9 | inner hexangular spanner | One set |

Pre-sales Service

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

After-sales Service

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 1 year

4. Engineers available to service machinery oversea

Our Service

1.Bending tools and accessories-Customized to your specifications

In our bending tools, our focus is on first-class, practical, well-thought-out upper and lower tools. Our tools offer solutions to your application cases - even for complex technical ones.

2.Service package

Basic:we offer you rapid troubleshooting through telephone support and costs for on-site missions are reduced.

Special:Engineers available to service machinery overseas for the necessary maintenance.

Partner:Our located dealers or customers who sell or use our machines are fully behind you,they are our friendly partner and supply good advice to you.

3.Technical Service(After-sale service)

Installation and start-up(Available for complex and big machines or if you have demand)

RFQ

Payment Terms:

T/T,L/C,D/P,D/A and soon on.You can consult with me,we will satisfy your needs.

Guarantee period:

Our product quality guarantee period is 24 months from B/L date. During guarantee period, we will provide spare

parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by

customers incorrect operations, we will provide customers spare parts at cost price.

We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the

round-trip air tickets, visa formalities, food and accommodation.

In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

A.Our company is a real professional exporter and we specialize in manufacturing

numerical control machine.

B.We must give you reasonable prices,because we want to become your sincere friend.

.jpg)

.jpg)